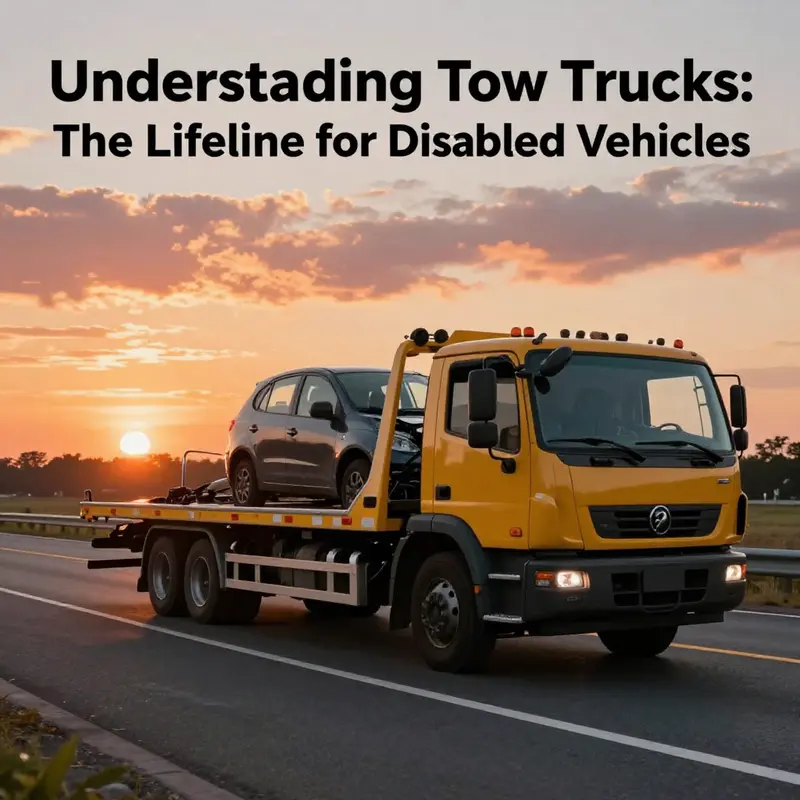

Tow trucks are pivotal in roadside assistance and vehicle recovery, serving every driver from everyday commuters to truck owners. Understanding how these specialized vehicles work, the variety they come in, and the regulations governing their operation can not only help you in emergencies but also enlighten property managers, auto repair shops, and residents on the importance of roadway safety. This article will delve into the types of tow trucks and their uses, explain their mechanisms and functionality, and highlight the essential safety regulations that ensure reliable service. Each chapter builds on the previous to provide a holistic view of what tow trucks are and how they play a crucial role in our transportation infrastructure.

null

null

The Mechanism and Mastery of Tow Trucks: How Roadside Relievers Lift, Move, and Rescue Vehicles

The Mechanism and Mastery of Tow Trucks: How Roadside Relievers Lift, Move, and Rescue Vehicles

Tow trucks are often understood as the practical workhorses of the road, yet their true complexity lies in the seamless interplay between weight, leverage, and precision. A tow truck is not merely a vehicle with a hook; it is a carefully engineered system designed to recover, secure, and transport vehicles that cannot operate under their own power. The core of its value rests on the reliability of its mechanisms and the skill with which operators deploy them. To many drivers, a tow truck appears as a single purpose asset—get under the bumper, lift, and haul away. In practice, the job unfolds as a sequence of precise judgments and micro-operations that begin the moment a breakdown or obstruction is detected and end only when traffic resumes its normal flow with minimal risk to people and property.

At the heart of the tow truck’s function is the principle of controllable restraint. The vehicle must be able to connect to another vehicle in a way that resists the forces of gravity, road irregularities, and, sometimes, the abrupt movements of other traffic. The lanes around an incident are rarely calm. Even in daylight, the scene can present gusts of wind, glare from headlights, spillages, and debris on the pavement. The operator’s first responsibility is to assess the scene and select a mechanism that offers sufficient control while minimizing the potential for damage to the disabled vehicle or to surrounding objects. This decision is rarely a binary choice; it often involves a spectrum of trade-offs among speed, safety, and the likelihood of additional wear or harm.

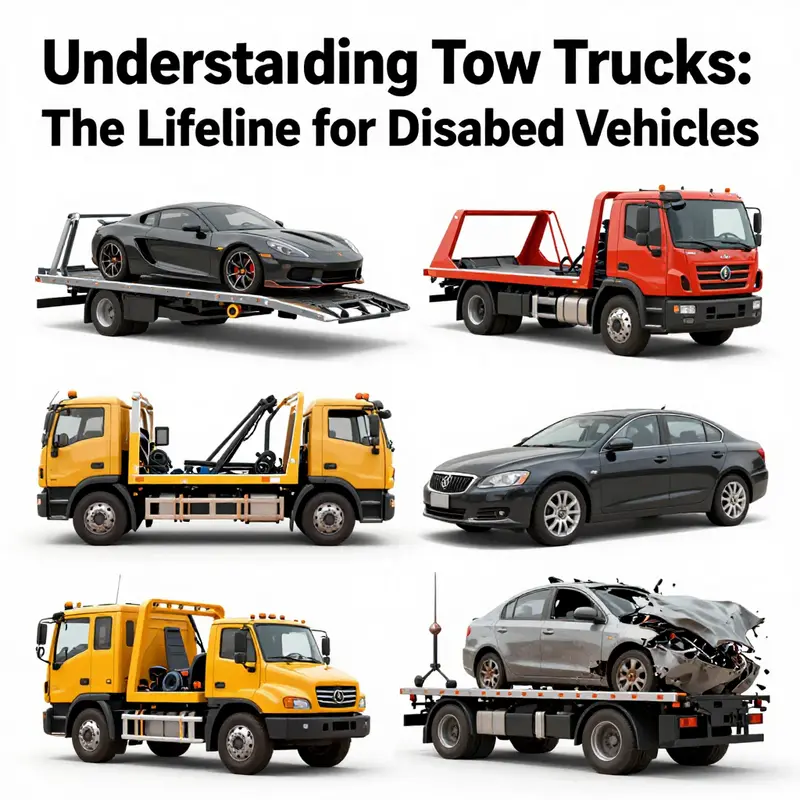

The three primary mechanisms of tow trucks—the wheel-lift, the flatbed, and the rotator—each have a distinct logic, suited to specific scenarios, vehicle types, and environmental constraints. The wheel-lift, sometimes known in older terminology as a hook-and-chain system, relies on gripping the front wheels with a hydraulic yoke or crane. The wheel-lift is fast and effective for many urban recoveries and is well-suited to vehicles that sit relatively level on the ground. It minimizes the space needed to perform a drag and tow, which can be an important advantage when maneuvering around parked cars or constrained roadside spaces. However, its use demands careful alignment and care. Lifting a vehicle through its wheels concentrates forces on the axle and suspension and can stress the frame if the vehicle is not properly balanced or if the balance shifts during the lift. Operators counter these risks with meticulous setup, using wheel chocks, proper strap angles, and gradual lifting to confirm that all components engage cleanly before the tow begins.

The flatbed—often called a roll-back for the way the bed tilts and slides under the vehicle—represents a different approach. The entire vehicle is transported with all four wheels off the ground, nestled on a hydraulically operated bed. The ingenuity of the flatbed is in its universality and its ability to handle a broad spectrum of vehicles, from luxury sedans to all-wheel-drive imports and slightly damaged trucks. Because the towed vehicle is never in contact with the road during transport, the risk of road debris, uneven pavement, or drivetrain stress is dramatically reduced. Drivers may lean toward flatbeds when the objective is to preserve a vehicle’s condition for resale or for a precise transport to a repair facility or storage depot. The flatbed’s design also makes it a pragmatic choice for vehicles that have transmission or steering issues which would render wheel-lift methods unsafe or ineffective. The process, though sometimes slower to deploy than wheel-lift, pays dividends in the final state of the vehicle and in the control the operator maintains throughout the move.

The rotator, equipped with a hydraulic boom capable of rotating through a full 360 degrees, represents the pinnacle of adaptability in tow-truck design. A rotator is not simply a lift; it is a flexible, multi-angle recovery system. Its operators can approach a vehicle from almost any angle, reach over barriers, and position a compromised vehicle into a stable, controlled configuration for lifting. This is essential in complex recoveries—vehicles resting on their sides in ditches, overturned trucks, or cars jammed between obstacles where conventional methods fail. A rotator’s versatility comes with higher costs and a steeper learning curve. Its operation requires rigorous training, constant attention to balance, and a clear plan for stabilizing the scene before and during any lift. On a windy hillside, in a tight urban alley, or on a roadside embankment, the rotator’s rotating boom can be the difference between a successful recovery and a hazardous stalemate.

Beyond these core mechanisms, a tow truck carries an array of auxiliary tools that extend its capability. Winches provide controlled pulling power, while hydraulic jacks lift and level vehicles to the exact point where a mechanism can take effect. Hydraulic systems deliver measured force to the bed or boom, ensuring loads remain within safe limits while enabling smooth, incremental movements. Safety devices, such as tie-down straps, wheel nets, and chocks, are essential to secure the vehicle and prevent shifting during transport. In more complex operations, it is common to see the rotator use its winch in tandem with the boom to position a vehicle, then lift it into a stable stance ready for transport. The synchronization of these tools speaks to the sophistication of modern tow operations and to the careful choreography that defines professional recovery work.

The choice of mechanism is never arbitrary. Vehicle type, the severity of the incident, road conditions, and the surrounding environment all shape the decision. A small car tangled in a roadside ditch on a wet night demands different tactics than a luxury sedan with intact tires in a crowded urban curb. A heavy-duty truck that has rolled off a highway shoulder may require the reach and precision of a rotator to minimize further damage while extracting it. Meanwhile, a routine roadside assist for a dead battery might be efficiently handled with a wheel-lift that minimizes setup time. Each scenario tests a different facet of the operator’s judgment, training, and experience. The operator must anticipate how the vehicle will respond as the mechanism begins to apply force. A miscalculation can convert a simple tow into a secondary accident, so the best teams cultivate a culture of deliberate, stepwise progression—from scene assessment to securing points, from testing the grip to executing the lift, and finally to securement for transport.

This is where the technology of tow trucks becomes most evident. The modern fleet has evolved through better hydraulics, more robust materials, and smarter design that anticipates common failure modes. Advances in sensor feedback, load ratings, and braking integration contribute to safer, more predictable operations. The operator does not rely solely on sight and intuition; a growing set of telemetry and mechanical feedback informs decisions at every stage. The result is a system that can adapt to increasing demands—higher-value vehicles, tighter city streets, and faster response times—without sacrificing safety or reliability. The broader narrative of tow-truck technology and safety is well captured in the literature that tracks these developments and their practical implications for daily operations. For a concise, technical overview, see the resource on tow-truck technology and safety.

The practical reality of these mechanisms sits at the center of roadside recovery, but the context surrounding their use is equally important. The operator’s skill extends beyond mechanical proficiency. It includes situational awareness, traffic control, and an understanding of local regulations that govern towing operations. Traffic in the immediate vicinity must be slowed or stopped in a controlled fashion through the use of warning lights, cones, and, when necessary, police coordination. The operator must also comply with local and national rules about how long a vehicle may stay on a tow bed, how it is secured, and how the load is distributed on the carrier. Failure to respect these rules can lead to on-scene penalties, liability for damages, or unsafe conditions for bystanders. The human element, then, remains a central thread in the story of tow trucks. The best teams combine mechanical precision with a disciplined approach to safety, communication, and professional ethics.

In the broader arc of vehicle rescue, tow trucks perform a role that blends mechanical art with logistical necessity. The ability to move a vehicle from a compromised position to a repair facility or impound yard hinges on a delicate balance: maximize control while minimizing further harm. A well-choreographed operation reduces the risk of secondary accidents, protects the integrity of the disabled vehicle for inspection or repair, and shortens the disruption to traffic. This is not merely about restoring mobility; it is about restoring order in a moment of disruption. The two ends of the spectrum—speed and safety—converge in every real-world tow, and the choice of mechanism becomes a practical expression of that convergence. Wheel-lift offers speed in routine cases, flatbeds emphasize safety and vehicle preservation, and rotators deliver the flexibility necessary for the most challenging recoveries. Each has a clear purpose, and together they form a toolkit that can adapt to almost any roadside scenario.

From a historical standpoint, the evolution of tow trucks reflects a sustained effort to handle more complex recoveries with greater reliability. Early tows relied on simpler devices and manual setups, often exposing operators to higher risk. Modern tow trucks integrate hydraulics, robust chassis designs, and a suite of stabilization features that reduce the likelihood of a tipping or shifting load. The progression from basic tows to highly engineered recoveries mirrors the broader professionalization of roadside assistance and fleet management. While the language around the job may emphasize the dramatic moment of a lift, the day-to-day reality involves meticulous preparation, precise execution, and a deep respect for the limits of both equipment and the road. As the industry continues to evolve, so too will the ways we think about safety, efficiency, and accountability in the field.

The mechanisms discussed here form the backbone of what tow trucks do. Yet perhaps the most important takeaway is not the specific gear, but the discipline that governs its use. A effective tow hinges on assessment, alignment, restraint, and controlled release. It depends on the operator’s ability to foresee how each component behaves under load and to adjust accordingly. Precision is the silent partner in every successful recovery, guiding the chain, the hook, the bed, or the boom through a sequence that can be completed in minutes or extended over an hour or more depending on the complexity of the incident. In the end, the roads are safer because these machines exist, and the people who operate them are trained to make difficult decisions quickly and conscientiously.

The broader article on what a tow truck is benefits from understanding these mechanisms not as isolated pieces of hardware, but as integrated systems designed to protect lives, minimize damage, and restore mobility promptly. The evolution from simple towing devices to sophisticated, multi-functional recovery platforms reflects a profession that blends engineering, judgment, and a steady hand. For readers who wish to explore the technical threads further, the pathway lies in exploring the balance between capability and caution that defines modern tow operations. The mechanisms do more than pull or lift; they embody the careful physics of safety and the social contract of service on the busiest arteries of our communities. In that sense, a tow truck is a moving intersection of technology, responsibility, and relief at times of stress on the road.

External resource for further reading: https://www.towtrucks.com/new-tow-truck-prices-overview-key-features-specifications-and-industrial-applications-explained/

Legal Standards and Safe Practices: How Tow Trucks Keep Roads Moving

Regulations and Best Practices for Safe Tow Truck Operations

Tow trucks are more than rolling tools for removing stranded vehicles. They operate where risk is concentrated: on shoulders, at crash scenes, and in live traffic. For that reason, regulation and disciplined practice shape how towing is done. Since 7 November 2022, updated technical standards have raised the bar for tow truck safety. Those standards emphasize structural integrity, braking capability, and performance under the stresses of crash towing. They also extend beyond hardware to how a tow truck presents itself at a scene, who can appear to represent public authorities, and how operators conduct themselves under pressure.

The new technical requirements aim to reduce secondary incidents, protect roadside workers, and preserve the vehicles being recovered. Tow trucks must meet specified construction and maintenance criteria before receiving a vehicle licence. Inspections focus on chassis strength, secure attachment points for towing gear, and redundancy in critical systems. Braking systems come under particular scrutiny. Tow trucks often slow or stop traffic as they position towed vehicles, so their brakes must provide controlled deceleration even under heavy loads. Enhanced brake testing standards target consistent performance during long descents and in emergency maneuvers.

Crash towing introduces added complexity. Vehicles involved in collisions can be structurally compromised, have leaking fluids, or contain airbag and fuel system hazards. The standards require specialized equipment and certified operator competence when handling these vehicles. Some public entities and agencies maintain highly prescriptive operating procedures for crash scenes. Tow trucks engaged in crash towing must comply with scene management protocols, including communication with police and emergency services, securement of hazards, and traffic control until recovery completes. These controls reduce the risk that a towing operation becomes the focus of a new emergency.

A notable regulatory restriction concerns the appearance of tow trucks and their crews. Vehicles used in crash towing may not display restricted names, logos, or insignia that could imply official authority. This rule prevents private operators from presenting themselves as government or emergency agency assets, avoiding public confusion. The restriction applies equally to clothing worn by towing personnel when working at crash scenes. Unless the relevant public body grants explicit written consent, tow operators must avoid markings that mimic official uniforms or vehicle liveries. The intent is simple: only authorized entities should look and act like they represent public agencies.

This visual clarity has practical safety implications. When first responders and drivers arrive at a scene, they must quickly identify who is a police officer, a paramedic, and who is a private operator. Misleading markings can cause delays or misdirected commands. A clear, regulated appearance reduces hesitation and ensures that scene control remains with properly authorized personnel.

Modern tow trucks now combine regulation-driven design with innovations that make recovery safer. Flatbed, or rollback, systems are a prime example. Rollbacks use a hydraulically operated bed that tilts and slides to ground level. A disabled vehicle is winched or driven onto the bed and secured. Because the towed vehicle’s wheels do not touch the road, rollback towing minimizes drivetrain stress and reduces the risk of further damage. It also improves stability during transport, especially in poor weather or on uneven surfaces. Regulatory guidance increasingly favors flatbed recovery for severely damaged vehicles, motorcycles, and cars with exposed undercarriages.

Beyond the bed itself, modern tow trucks incorporate stability controls, redundant winch systems, and integrated load sensors. Load sensors ensure that winches operate within safe ratings. Integrated controls can limit boom angles or prevent winch operation when the truck is on an unsafe grade. These features are a response to incidents where improper rigging or overloading caused equipment failure and injury. Standards now demand that manufacturers and owners provide clear load-rating documentation and require periodic verification of winch and boom performance.

Operator competency is central to safe towing. Regulations increasingly require documented training and proof of proficiency for drivers who work in crash towing. Training covers vehicle dynamics, securement methods, hazard recognition, and scene safety protocols. It includes hands-on exercises in loading heavy or irregular cargo and simulated work on busy roads. Training also teaches communication practices with emergency services, so towing teams integrate smoothly with police and rescue crews. A certified operator understands when to call for specialized recovery equipment and when to defer to heavy-recovery teams.

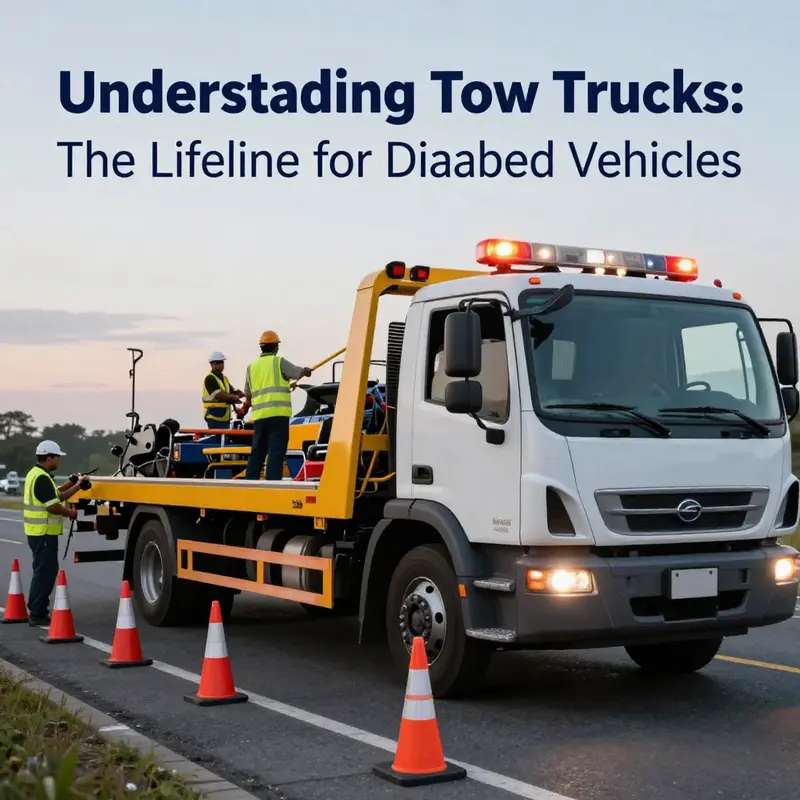

Personal protective equipment and on-scene ergonomics receive similar attention. High-visibility clothing must meet standardized reflectivity levels. Gloves, eye protection, and sturdy footwear reduce common injury vectors. Lighting plans for night operations mandate portable work lights, reflective signage, and placement of safety cones. These measures protect both the crew and passing motorists. Scene lighting and high-visibility gear make a lane closure or temporary slowdown more evident and reduce the risk of secondary collisions.

Traffic management is often a separate but tightly linked discipline. Effective traffic control plans limit how much of the live lane is obstructed, provide clear diversion paths for motorists, and establish a safety buffer for crews. Tow operators coordinate with traffic authorities and police to set up cones, portable signs, and arrow boards. The objective is to create predictable traffic flow around the incident. Predictability reduces erratic driving behavior that can cause further incidents.

The regulatory framework also governs documentation and accountability. Operators must keep accurate records of recoveries, equipment inspections, and training certificates. These logs support enforcement and help owners track maintenance cycles and incident histories. In the event of disputes or legal action, clear documentation demonstrates compliance with applicable standards. Insurance companies and public agencies often require these records before permitting a tow truck to perform crash towing work.

Maintenance regimes are part of the safety equation. Tow trucks endure heavy cycles: repeated winching, lifting, and braking under load. Regular inspections catch fatigue cracks, hydraulic leaks, and brake wear before they cause failure. Preventive maintenance schedules typically include visual checks, load-test cycles for winches and cylinders, brake system servicing, and examination of electrical systems that power lights and controllers. Regulations often specify minimum inspection intervals and require repair records.

Equipment selection, installation, and securement matter. Tow hitches, chains, straps, and clamps must meet strength ratings appropriate to the heaviest vehicle a truck may tow. Using the right attachment for the vehicle type prevents slippage and reduces stress on connection points. Load distribution devices, such as equalizers and draft bars, help manage dynamic forces during towing. Properly matched equipment and certified rigging practices prevent failures that can cause road spills or dropped loads.

Hazardous materials and fluid spills are a frequent concern with crash towing. Vehicles that leak fuel, oil, or coolant create fire and environmental risks. Operators must be trained to assess and contain spills, using absorbent materials and spill kits. Regulatory frameworks often require immediate notification to environmental or road authorities when hazardous leaks occur. Rapid containment reduces the long-term cleanup burden and lessens exposure risks to the crew and public.

Lighting and signage standards receive precise treatment. Tow trucks must display appropriate amber warning lights, recessed strobe systems, and visible reflective striping. When operating on high-speed roads, additional signage, such as portable arrow boards and variable message signs, provide early warning to approaching drivers. Lighting placement and intensity are regulated to ensure visibility without impairing other drivers’ vision. Modern regulations also govern how lights flash and whether they may be used while moving.

Legal liability and insurance intersect with safety rules. Compliance reduces exposure to claims arising from secondary collisions or damage to vehicles in recovery. Insurance providers often offer lower premiums to fleets that demonstrate rigorous maintenance, certified training, and documented compliance with scene protocols. Conversely, failure to meet standards can lead to regulatory fines, revocation of licences, and civil liability.

Coordination with emergency services is a daily reality for many tow operators. Police and fire services rely on qualified towing providers to clear scenes quickly and safely. Formal agreements or memoranda of understanding typically outline responsibilities, response times, and acceptable markings. These agreements ensure a shared understanding of expectations and reduce friction during time-sensitive recoveries.

Technology contributes to safety through tighter integration between vehicle systems and operator controls. Telemetry can record winch loads, vehicle angles, and brake status. Fleet management systems track service intervals and log operator qualifications. This data supports continuous improvement and helps regulators verify compliance. When a critical incident is investigated, telemetry and service records provide objective evidence of how an operation was conducted.

Community expectations shape practice as well. When a tow truck appears at a crash, bystanders often assume it represents an authority. The regulation limiting logo use ensures that private operators cannot imply endorsement by public bodies. That clarity protects both the public and honest operators who work within the rules.

Operators can take concrete steps to maintain compliance and enhance safety. First, adopt a formal training and certification program for all recovery personnel. Second, implement a rigorous preventive maintenance schedule aligned with manufacturer guidelines. Third, standardize rigging and securement practices using rated equipment and documented procedures. Fourth, coordinate with local emergency services to establish clear roles during crash responses. Fifth, maintain thorough records of inspections, repairs, and training.

Adapting to new standards can be operationally disruptive, but the long-term benefits outweigh the short-term costs. Improved safety decreases incidents that injure workers or drivers and reduces vehicle damage claims. Higher reliability and predictable performance build trust with emergency services and insurers. Standardization across a region enables more consistent responses to multi-vehicle incidents and improves mutual aid among towing providers.

Regulatory updates, like those introduced in November 2022, reflect lessons learned from past incidents and technological advances. They do not eliminate risk, but they shape a system where risk is anticipated and managed. The result is a safer environment for roadside workers, a more dependable service for stranded motorists, and smoother traffic flow after incidents.

For operators and fleet managers, staying current with regulation requires active engagement. Subscribe to updates from licensing authorities, participate in industry working groups, and invest in training and equipment that meet or exceed standards. When public agencies publish specific procedures for crash towing, integrate them into your standard operating procedures. Regular audits of both documentation and equipment help identify gaps before they become liabilities.

Finally, the human element cannot be overlooked. A well-trained, disciplined crew reduces mistakes and responds clearly under stress. Clear communication, proper attire, and a consistent visual identity that complies with the law help the public and first responders interact effectively at scenes. Tow truck safety is a system: equipment, people, training, protocols, and regulation all work together to keep roads moving and reduce harm.

For a detailed overview of the regulatory changes referenced here, see the official guidance on new industry standards at the Small Business Development Corporation’s article: https://www.sbdc.org.au/blog/new-regulations-for-the-tow-truck-industry. For further practical guidance on modern systems and safety protocols, review material on tow truck technology and safety available from industry resources such as tow truck technology and safety.

Final thoughts

In summary, a well-rounded understanding of tow trucks encompasses their diverse types, intricate mechanisms, and stringent safety regulations. Whether you are an everyday driver, a property manager, or an auto repair shop owner, the knowledge of how tow trucks operate and are regulated can enhance both your preparedness for roadside emergencies and your ability to ensure safer highways. Recognizing the critical role these vehicles play may cultivate a greater appreciation for the services they provide in keeping our roads running smoothly.