Across roads and repair yards, a tow truck is more than a vehicle—it’s a mobile service platform. A rarer but practical scenario occurs when a recovery unit itself must be moved while still in service: one tow truck towing another. This can happen when a tow vehicle suffers a breakdown, sustains damage, or simply needs relocation between depots or job sites. In each case, the towing unit must carry the disabled asset without compromising safety, braking, or control. The operation tests the limits of power, traction, and winching systems, and demands disciplined procedures to shield both vehicles, the operators, and surrounding traffic from harm. This article unpacks the topic through five tightly linked angles. Chapter 1 explores mechanical failure, safety protocols, and readiness to move a disabled asset. Chapter 2 examines accident response, recovery procedures, and on-road logistics. Chapter 3 delves into equipment configurations, winching methods, and load management under dual-tow conditions. Chapter 4 considers the economic implications for fleets, asset utilization, and downtime costs. Chapter 5 addresses regulatory requirements, training needs, and public safety considerations. The framework is designed for Everyday Drivers, Residents & Commuters, Truck Owners, Auto Repair Shops & Dealerships, and Property Managers who may encounter this unusual but important recovery scenario. Each chapter builds on the last to illuminate how expertise, equipment, and coordination keep these critical recoveries efficient and safe.

Chapter 1: The Double Tow — Navigating Mechanical Failure, Safety Protocols, and Operational Readiness When a Tow Truck Tows Another

A tow truck towing another tow truck is more than a curiosity on a busy road; it is a tightly choreographed operation that rests on discipline, planning, and an exacting regard for safety. In the world of heavy-duty recovery, the need to move a disabled vehicle often arises not from choice but from consequence: a breakdown that freezes a unit in place, a coupling that has to be moved from one location to another, or a depot-to-site transfer where the vehicle itself cannot complete the journey under its own power. The resulting scene—a functioning tow unit pulling a nonfunctioning partner—unfolds with the same underlying objective as any rescue: minimize risk to personnel, other road users, and the equipment, while preserving the integrity of both vehicles. Every successful double tow begins long before the cord is connected, with a comprehensive assessment that respects the weight, balance, and mechanical state of both machines and the road conditions that will govern their passage.\n\nTo begin, a careful pre-job briefing sets the tone. The operators review the nature of the emergency, the relative positions of the two trucks, and the route that will be taken. They confirm the towing method that best suits the disabled unit: a heavy-duty tow bar, a winch setup, or a flatbed option, depending on what the towed truck can safely endure during transit. In a double-tow scenario, the margin for error is small; obvious but critical checks follow. The towing vehicle must have sufficient pulling capacity, and the towed unit must be secured in a way that remains reliable under road irregularities. The choice of coupling device matters as much as the choice of route, because even a momentary detachment during acceleration or on a slope can escalate into a controllability problem with costly consequences. The discipline of lockout and chain management, the use of rated straps, and the avoidance of improvised or makeshift connections are non-negotiable. If the operation happens on a roadway, the plan must include traffic control: amber warning lights, possibly a staged cone or flare setup, and a clear, reduced-speed regime that respects the physics of two heavy vehicles moving as a single unit.\n\nThe inspection that precedes any tow has two halves: the towing truck and the disabled truck. For the towing unit, a focus on braking systems, tires, suspension, and the hitch or coupling mounts is essential because any weakness here will be amplified when the vehicle is under load. The towed truck, even when it is only being moved to a repair shop or a depot, requires a structural assessment. The chassis, axles, and mounting points must be sound enough to bear the hydraulic pull and the inertia of motion. In both vehicles, a check of the winch line, cables, or the tow bar is essential. The goal is not to rely on a single failed component but to ensure redundancy at critical points of connection. The operators need to communicate constantly. A simple, pre-agreed set of hand signals or radio protocols enhances safety, especially when visibility is compromised by weather, traffic, or the stealthy dynamics of a moving recovery.\n\nThe operation itself is a balance of physics and timing. The tow truck’s engine must deliver steady torque without overwhelming the towed unit’s structure. Drivers must maintain a controlled pace, slower than normal traffic speed, with careful attention to wheel alignment and slip. Sharp turns are avoided; the geometry of the two vehicles must be kept within a safe envelope to prevent side loading or undue flex on the tow bar. In some configurations, the towed truck’s wheels may be on a dolly or on a platform that distributes weight more evenly; in others, a flatbed might be deployed to secure the disabled vehicle as a single unit. Either way, the selection is driven by the aim to reduce damage to the disabled vehicle and to prevent the towing system from becoming a hazard in motion. The plan extends to braking. Maintaining a safe distance between the two vehicles is critical because the stopping distance for a tandem arrangement is longer than for a single machine, and any sudden deceleration can transfer stress directly to the connection point, possibly triggering a failure if the equipment is near its limits.\n\nA robust safety framework anchors this entire process. High-visibility clothing, illuminated signaling, and the position of crew members to minimize exposure to traffic are all deliberate choices designed to reduce risk. The operators are trained to manage emergencies, including a detachment scenario or an unexpected vehicle sway that could occur if the towed unit’s weight distribution shifts suddenly. Systematic checks—such as confirming that the towed truck is aligned, that the tow bar remains locked, and that the winch’s motor temperature does not indicate overload—function as ongoing safeguards. In parallel, rhythm and cadence matter. The drivers should be in constant communication to synchronize acceleration, steering, and deceleration, ensuring the tow line does not experience shock loads that might lead to a snap or buckle. A calm, methodical tempo becomes the most powerful safety feature; haste is the adversary of control in these operations.\n\nBeyond the mechanics, the regulatory and standards framework provides a scaffold for professional practice. Even when a tow operation occurs outside of a formal roadway scenario, the emphasis on planning, inspection, and controlled execution echoes the broader safety culture that governs heavy recovery work. While no single regulation speaks exclusively to the act of towing a tow truck, general workplace safety standards influence how teams approach such tasks. Industry bodies and national safety administrations offer guidance that is applicable in practice: maintaining equipment readiness, limiting speed, and ensuring robust protective measures in the presence of moving machinery. The aim is to translate knowledge from general heavy-vehicle handling into the specific, stringent requirements of a double tow.\n\nIn practice, the double tow also raises questions about locale-specific safety practices and enforcement. Local inspection regimes may require that towing operators hold certifications, that the vehicles be properly identified with reflective markings, and that the operation adheres to a defined set of procedural rules when performed in urban or congested environments. Such rules often translate into a checklist that operators use to confirm roll-call readiness: ignition status, braking response, and the integrity of the grounding of electrical components. The human factors—communication, situational awareness, and the willingness to pause if conditions deteriorate—remain the constant companions of any double-tow mission. Operators must be prepared to forgo the move if even a single element is uncertain. The practice demands humility: the strongest tow teams are those that recognize limits as quickly as they recognize opportunities.\n\nFor those who want to ground these reflections in concrete, locale-specific guidance, a practical point of reference is the Tow Truck Safety Checklist, which captures essential actions from registration and insurance to operational readiness and on-site conduct. See the practical framework at Tow Truck Safety Checklist (NYC.gov). This resource anchors the complex, often technical details in a common-sense, enforceable standard that operators can adapt to their own jurisdictions while maintaining the shared language of safety and professional responsibility.\n\nAs the chains and bars settle into their places and the two machines move in tandem, the broader significance of this double-tow operation becomes evident. It is a testament to the professional discipline of heavy-duty responders who keep traffic moving and incidents contained, even when the task is as unusual as towing another tow truck. The double tow sits at the intersection of mechanical reality and human vigilance; it is where the road tests a crew’s preparedness, and where a well-executed plan proves its worth through the smooth, deliberate, and safe transfer of energy from one vehicle to another. The operation embodies the essential ethos of recovery work: readiness, restraint, and respect for the limits of both equipment and circumstance.\n\nExternal reference: for a broader perspective on how these operations are analyzed from a safety and engineering standpoint, see https://www.nhtsa.gov/vehicle-safety/dump-truck-recovery-operations

Tow on Tow: Precision, Protocol, and the Logistics of Recovering a Disabled Tow Truck

On a sunlit highway or a dim roadside, a scene unfolds that most drivers never see and few ever expect. One tow truck, built to pull others from trouble, becomes the vehicle that must be towed because one more breakdown has left the fleet temporarily immobilized. The image of a tow truck towing another tow truck sounds almost paradoxical, yet it is a practiced, carefully choreographed operation. It is less about performance spectacle and more about safety, precision, and the logistics of moving heavy, precision-engineered machinery under pressure. In such moments, the goal is not to hurry a recovery but to control every variable—weight distribution, attachment geometry, slope, surface condition, and the sequence of maneuvers that will separate risk from rescue. The procedure embodies a utility philosophy: the right machine, in the right configuration, with the right operator, at the right moment.

Central to most recoveries of this kind is the 20-ton wrecker, a workhorse designed to lift, pull, and secure without unduly stressing the struck equipment. Its rotating boom can reorient the load while the vehicle remains stationary, or the operator can guide a damaged truck toward a safe position with minimal wheel contact. The adjustable arms reach to grab frame members or recovery points with a controlled arc, while a dual winch system allows one line to take the pull while the other holds opposing forces for stability. This combination lets crews guide a disabled truck from a ditch, a roadway shoulder, or a soft shoulder into a planned transport path without improvisation. The aim is not just to move weight but to do so with precision that reduces collateral damage to the vehicle being towed and to nearby obstacles and people.

Some recoveries employ a hydraulically operated flatbed, a rollback variant that can load the disabled vehicle onto a platform where it can be secured for road transport. The advantage is clear: minimizing ground contact reduces scuffing, further damage, and tire failures. The disabled tow truck can be winched or driven onto the bed in a controlled sequence, with the platform offering a stable, level base for the load. This is particularly important when the towed vehicle has sustained structural damage or when its steering components are compromised. Yet a flatbed adds complexity, because loading operations must be synchronized with the primary recovery vehicle. The crew must meter the bed’s angle and the drive-up sequence, ensuring that no unintended twist or lift occurs during the transfer.

Every option carries trade-offs. A 20-ton wrecker demands meticulous maintenance. The rotating mechanism, winches, and hydraulic systems require regular inspection, lubrication, and testing. The wrong maintenance interval can turn a routine rescue into a complicated, hazardous operation. The initial investment is nontrivial, but so is the ongoing cost of fuel, tires, spare parts, and specialized training. The alternative, a heavier class, increases lifting capacity and stability but expands the equipment’s footprint, reduces maneuverability in tight spaces, and raises cost. Operators must balance capacity against site constraints, weather, and the expected duration of the recovery. The broader implication is that the success of pulling a tow truck is less about brute force and more about matching the asset to the challenge, then executing the plan with discipline.

When conditions demand more than the baseline, a 50-ton wrecker steps into the narrative. In overturned or severely damaged scenarios, or when the terrain is uneven and space is constrained, the extra lifting capacity and the second point of stabilization become essential. A heavier rig can manage extreme angles, spread loads across multiple points, and maintain a safer stance on gravel, mud, or shoulder debris. The advantages are counterbalanced by higher costs, longer setup times, and the need for operators with advanced training. The vehicle’s larger footprint can complicate onboarding and reach, requiring careful path planning from depots to accident sites. In practice, the choice between 20-ton and 50-ton assets hinges on weighing the likelihood of severe outcomes against the probability of encountering uncompromising terrain. The decision is rarely theoretical; it is guided by local geography, traffic volume, and past incident patterns.

On the scene, recovery is a ballet of communication. Real-time updates, disciplined radio discipline, and preplanned sequences keep the operation from becoming chaotic. The team must assess the disabled truck’s weight, the orientation of its frame, and environmental constraints such as slope, surface friction, and nearby hazards. Without a clear plan, a single misstep can cause secondary damage or injuries. The crew selects the appropriate wrecker size, checks rigging points, and ensures anchor points can bear combined loads. They perfect the pull by testing tension in increments, watching the booms for deflection, and adjusting as needed. The goal is to maintain control at every stage, from arrival through hook-up to final positioning for transport. In this domain, safety protocols and environmental awareness are not add-ons but fundamental, guiding principles that shape every movement.

Attachment details matter as much as the machines themselves. The tow bars, wire ropes, hooks, and straps must align with the disabled vehicle’s frame and recovery points. The crew secures wheels with chocks, applies temporary braking on the towing vehicle if needed, and positions the second unit to avoid entangling lines with traffic or other equipment. The use of a rollback flatbed can reduce rope wear and side loading but requires precise alignment so the load sits squarely on the bed. The operator’s hands move in slow, deliberate sequences, each action announced and confirmed by teammates. The result is a stable, repeatable process rather than a hurried, improvisational sprint. While the 20-ton system handles most standard recoveries, the 50-ton option remains in reserve for when the geometry of the scene demands it, and the operator’s training proves its worth in tension and time saved.

Recovery work is a craft shaped by guidelines and practice. Teams study the limits of their gear, rehearse rigging plans, and run drills that simulate accident scenes and off-road conditions. The value of this preparation is measured in avoided damage to assets, reduced exposure to risk, and faster stabilization times. It also reinforces the ethical dimension of recovery work: the need to safeguard people, preserve property, and respect the surrounding environment. The line between successful and catastrophic outcomes is often the margin by which a crew anticipates angles, loads, and friction. That margin is built through training, checklists, and clear communication, all of which reduce the likelihood of improvisation on the roadside. This is why comprehensive response frameworks emphasize not only equipment capabilities but also the human factors that govern how teams think and react under pressure.

Ultimately, the ability to tow one tow truck with another is a testament to the adaptability of emergency fleets. It is not a single tool but a system that integrates equipment, people, standards, and logistics. When well executed, it allows a damaged asset to return to service quickly and safely, while protecting the integrity of the road system and the people who use it. For readers seeking deeper coverage of how training frames these complex recoveries, emergency response training best practices provide detailed guidance. emergency response training best practices. For a concise treatment of what a tow truck is and how it functions, you can consult a general reference at the British Council: https://www.britishcouncil.org/learnenglish/word-of-the-day/tow-truck

Tow Within a Tow: The Engineering, Precision, and Safety of Pulling Another Tow Truck

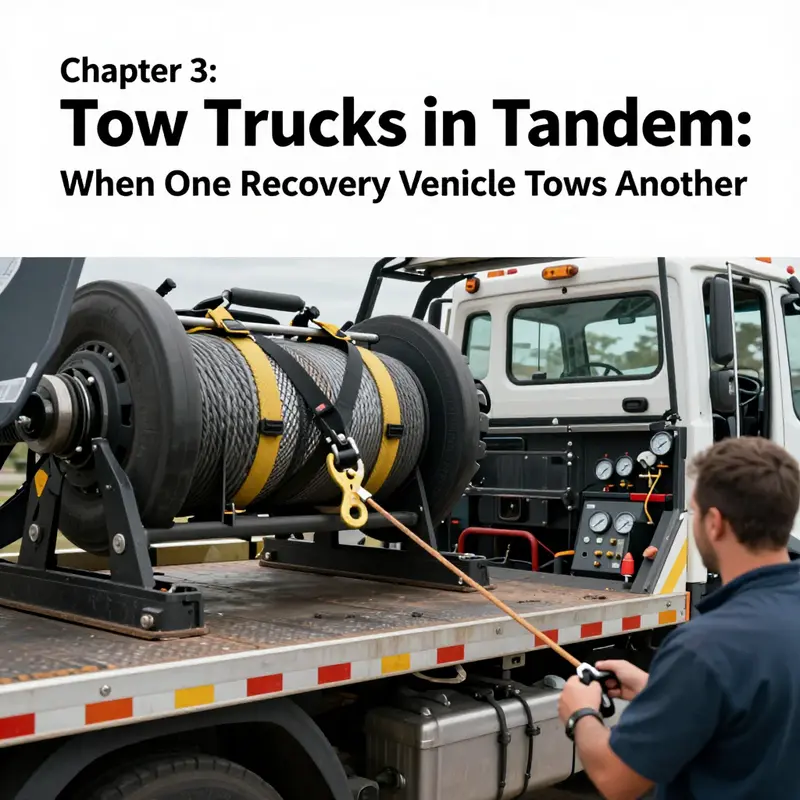

A tow truck towing a tow truck sounds paradoxical, almost ceremonial in a field built on momentum and speed. Yet in certain moments it is the only sensible path to move a failed unit without risking further damage, delaying a critical recovery, or stranding a stranded vehicle in inhospitable terrain. The scenario unfolds like a carefully choreographed rescue where the performers are heavy machines, the stage is asphalt or snow, and every movement reverberates through transmission gears, hydraulic lines, and the operators’ training. What begins as a routine depot transfer or roadside repair can quickly escalate into a test of equipment configuration, winching technique, and load management. A single misplaced bolt, a misaligned hitch, or an abrupt shift in weight can cascade into a fault that rivals the original breakdown. The story of one tow truck pulling another is, at its core, a story about limits—their boundaries, how to respect them, and how to stretch them safely when the situation demands it.

The rarity of the event, paradoxical as it seems, is not a measure of its importance. Tow trucks are designed to haul other vehicles, but when the hauled vehicle is itself a tow unit, the operation tests expectations and stretches the envelope of what the recovery truck can safely bear. It begins with a clear picture of why the disabled unit must be moved by another—mechanical failure that stops the drivetrain, steering lockups that render a vehicle unsteerable, or even the simple need to relocate a heavy unit from one depot to another for service. The operator faces a decision tree: can the disabled truck be secured on a flatbed, preserving its integrity for transport, or must it be winched directly, with the risks of maneuvering a live load? Each choice demands a precise appraisal of weight, length, and the road or terrain ahead. In such moments, the recovery vehicle becomes not only a tool but a safeguard, ensuring that the disabled machine does not become a hazard itself.

Equipment configurations sit at the heart of successful execution. The recovery tow truck must be equipped with a robust winching system—typically a heavy-duty hydraulic or electric unit capable of handling loads well in excess of the standard lifting capacity. The winch, a critical artery of the operation, is mounted on a reinforced chassis with strengthened frame rails and sometimes upgraded suspension. A properly rated tow hitch, often Class IV or V, along with integrated safety chains and a dependable braking system, forms the baseline for handling the combined mass of both vehicles. For the disabled tow truck, the considerations center on secure transport and minimizing the risk of collateral damage. When the vehicle cannot drive, a flatbed trailer or a dedicated tow-truck carrier is commonly used. If winching is chosen, the disabled unit must be immobilized with wheel chocks, and the brakes may need to be engaged to prevent any unwanted movement during the lift. In challenging recoveries, wheel dollies or axle stands can help distribute weight and shield vulnerable components from excessive stress.

Winching methods require both finesse and caution. The most common approach—direct winching from the front or rear bumper—is only safe when the vehicle’s structure provides solid attachment points. A purpose-built winch plate or snatch block system can dramatically improve mechanical advantage and reduce strain on any single portion of the recovery vehicle’s frame. The operator should anchor the line to frame rails or factory reinforced tow hooks rather than fragile components like damaged bumpers or lift brackets. A secondary safety line, cable, or chain is a prudent safeguard against cable failure. In terrain that tests balance—steep grades, loose soil, or snow—winch-assisted recovery with a secondary anchor point might be necessary. But this adds complexity and risk: frame deformation, lateral forces on the chassis, or unpredictable recoil if the pull shifts unexpectedly. Rigging must be calculated and checked before the line is tensioned; the aim is to convert potential energy into controlled motion rather than a chaotic hammering of metal and glass.

The heart of the operation is load management, and this is where preparation becomes reliability. The combined weight is not merely an arithmetic sum; it is a dynamic system with shifting center of gravity, varying drag, and changing traction as speed and terrain evolve. Before any movement, the recovery team must calculate the total mass—fuel, equipment, and even fluids—that the recovery truck will shoulder. Steering the tow in a straight line helps prevent torsional stress on both vehicles. Any misalignment risks uneven tire loading, suspension damage, and undue strain at the hitch. As the tow begins, the operators monitor tire temperatures, brake condition, and transmission fluid levels, watching for signs that the load exceeds what the truck was designed to bear. Speed becomes a discipline, not a habit: slow acceleration, smooth deceleration, and careful cornering to minimize inertia-related stresses. On long hauls, periodic inspections are essential. The task requires patience, because haste can magnify heat and wear in components that already carry more than their usual share of load.

This is not a routine road task but a performance of engineering discipline. The recovery team must visualize how forces flow through the system: the pull of the winch line, the resistance of the disabled vehicle, and the mass of both units moving in unison. The alignment between the two vehicles matters as much as the strength of the winch. When the disabled tow truck is pulled too far off its axis, the resulting torsion can tilt the frame, distort axles, or stress the hitch beyond its ratings. The operators refine the balance by adjusting hook points, using blocks to alter rope or cable angles, and, when necessary, repositioning the disabled unit to re-center gravity. Communication among crew members remains the unseen backbone—velocity cues, line tension readouts, and the joint decision to pause if the wind, weather, or road conditions demand a recalibration of the plan.

In terms of practical realities, the scene is rarely a single moment but a sequence that unfolds with careful staging. A common pattern begins with site assessment: is the ground firm enough to support wheel chocks and dollies? Are there obstacles that would complicate a straight line pull? From there, the recovery vehicle is prepared with a clear elevation path for the winch line, and the disabled unit is carefully positioned so its strongest attachment points align with the recovery vehicle’s working line. If a flatbed is used, operators must ensure a secure tie-down system that prevents shifting during transport, with blocks and chocks in place to constrain movement. If direct winching is chosen, the chain of steps includes securing a remote anchor point, pre-tensioning the line to eliminate slack, and verifying a back-up anchor as a precaution against failures. The goal is not speed but a measured, controlled motion that preserves both machines’ integrity while delivering the disabled unit to a service facility with minimal downtime.

For readers who wonder about the practical curiosity raised by the question itself—what does it cost, what capabilities are required, and how can one learn to perform such a recovery safely? The discipline rests on a mix of knowledge and certified practice, a balance of power and restraint. In many hands, a tow truck tow pulls another without drama, but it is a calculation-rich performance that respects weight limits, structural integrity, and the realities of road conditions. The operation demonstrates how tow trucks function beyond simply hauling on a straight road: they also serve as mobile laboratories for physics, metallurgy, and logistics. The system is only as strong as its weakest link, which is why-trained operators never improvise beyond the safety margins defined by their equipment, manuals, and regulatory guidance. For those curious about the financial or equipment specifics, a common starting point is to consider the market and the typical costs involved in ownership and operation—an area where the nuances of need, capacity, and service levels shape every decision. As one worth noting, the broader field stresses that safety and reliability must always precede speed or novelty.

In the broader arc of the industry, the scenario of a tow truck towing a tow truck underscores the essential role of recovery work in maintaining the continuity of service in a transportation network. It highlights how the advent of improved winching systems, smarter load distribution, and more robust attachments has expanded the safe envelope for complex recoveries. It also points to a broader truth about equipment and training: the best tool for a challenging job is not merely the strongest machine but the one paired with the right plan, the right people, and the right precautions. The recovery operator who treats the configuration as a living system—adjusting gear, rechecking lines, and communicating clearly with the crew—epitomizes the careful craft that keeps the towing world moving, even when the vehicle at the heart of the job has itself failed.

To tie this discussion back to practical curiosity and ongoing industry learning, consider the real-world questions drivers and operators ask when facing a tow-within-a-tow situation. How are the attachment points chosen? How is the hitch rated in relation to the total weight? How does terrain influence the choice between direct winching and using a flatbed carrier? These questions feed into the ongoing dialogue about safety, technology, and procedure that keeps roads safer and recovery operations more predictable. And while the scenario may be rare, its implications ripple through planning, training, and everyday decision-making in the world of heavy-duty towing. For readers seeking a concise primer on the economics of tow vehicles, there is a practical guide that outlines general costs and considerations—an anchor for those evaluating their own fleets. how much is a tow truck

External resource: For safety guidelines and regulatory context that frame these operations, see the National Highway Traffic Safety Administration’s towing and transportation guidance: https://www.nhtsa.gov/vehicle-towing-and-transportation

Tow Within a Tow: The Hidden Economics of Double-Tow Scenarios in Fleets

The image of one tow truck pulling another is not a joke about mechanical irony so much as a window into the fragile arithmetic of asset-heavy operations. In the real world, a tow truck may become the patient on wheels, disabled by a mechanical fault, a mishap, or the simple wear and tear that accompanies high miles and tight schedules. When that happens, the fleet does not pause to admire the irony; it calculates a second tow, a second crew, and a second bill. What begins as a practical recovery mission often ripples into questions of reliability, planning, and the economics that quietly govern every vehicle counted as an asset. This is not merely about moving a vehicle from point A to point B. It is about how, in a service business built on speed, dependability, and the promise of rapid response, a single breakdown can cascade into a far larger economic accounting than most managers anticipate. The second tow truck arrives not as a novelty but as a critical instrument for restoring service continuity, and in that moment the quiet politics of asset utilization and maintenance becomes a visible, measurable concern with real consequences for margins, customer trust, and long-term capacity planning.

The reasons a tow truck might need rescue are straightforward, yet their implications are layered. A mechanical failure—engine trouble, transmission issues, or a failing hydraulic system—can ground a truck just when the call load is rising. An accident can damage enough to render safe driving impossible, turning a mobile asset into a roadside recovery challenge. And even without an incident, logistics sometimes require moving a tow unit between depots, yards, or job sites, especially when the vehicle is not street-ready for a direct assignment. In each case, the response is similar: deploy a second, capable vehicle with the right winch, the right mounting, and the experienced crew to execute a secure, roadworthy transfer. The operation demands careful planning, strict adherence to safety protocols, and a clear chain of command to ensure the disabled unit is recovered without inflicting further damage or creating new hazards on the roadway. The equipment matters as much as the plan. A robust flatbed or a powerful recovery winch must do the heavy lifting while protecting hydraulic lines, tires, and undercarriage from additional strain. The goal is not just to move a vehicle, but to move it safely and efficiently, with minimal collateral disruption to traffic and to the fleet’s ongoing commitments.

From an economic perspective, the costs compound quickly. The direct expenses are tangible: additional labor hours, fuel for a second unit, wear on heavier-duty equipment, and potential overtime or hazard-pay charges for late or hazardous operating conditions. The more subtle, yet equally consequential, costs are the opportunity costs associated with tying up two high-demand assets on a single incident. A second tow truck absorbs the capacity that could have been used to meet another emergency, a routine service window, or a planned delivery. When the incident occurs during peak demand, or in regions with high call volume, these double-tow events threaten to widen the gap between what a fleet can promise and what it can deliver within promised timeframes. The customer impact—missed windows, delayed assistance, or the perception of unreliability—can translate into softer, but equally important, losses: reputational damage, reduced repeat business, and demands for compensation or revised service terms.

This is where the chapter’s core argument takes shape. Double-tow events are not merely anomalies; they reflect systemic vulnerabilities in preventive maintenance, driver training, and the overall design of asset utilization. If one truck can be repeatedly taken out of service without an adequate buffer in the fleet, management must reconsider either the sizing of the asset base or the safeguards around maintenance. A fleet that operates with lean staffing and a high utilization rate may feel justified in minimizing spare capacity, yet it is precisely that lean posture that makes each breakdown more painful and more expensive. The economics thus hinge on balancing reliability and cost: invest in preventive maintenance and more buoyant spare capacity, or accept a higher risk of cascading disruptions that erode service levels and profitability. The double-tow scenario serves as a diagnostic lens, exposing how well or poorly a fleet orchestrates routine upkeep, predictive checks, and real-time scheduling. It highlights the tension between the discipline of planned maintenance and the unpredictability that comes with road life.

To mitigate these risks, fleets increasingly lean on data-driven strategies that transform reactionary recovery into proactive resilience. Telematics, sensor data, and IoT-enabled diagnostics allow operators to detect early signs of mechanical stress—unusual vibration patterns, fluctuations in hydraulic pressure, or creeping fuel anomalies—before a breakdown occurs. Predictive maintenance moves from a philosophical ideal to a practical timetable, guiding replacements, part stocking, and service intervals with a precision that reduces the probability of disabling failures in the field. Fleet management software then steps in to optimize scheduling, track downtime, and enable dynamic rerouting so that the next call is never too far away, even if the current asset is temporarily sidelined. In this framework, the second tow truck becomes less of a surgical necessity and more of an anticipatory safeguard—an investment that preserves overall fleet availability and keeps response times within the bounds of customer expectations. The emphasis shifts from reactive patchwork to a cohesive reliability program that treats every asset as part of a broader, interconnected system. The aim is not to eliminate double-tow events entirely, which is impractical, but to compress their frequency and impact through smarter maintenance protocols, better training, and more robust equipment selection.

Even as technology extends its reach, the human element remains central. Drivers and technicians must be trained not only to perform the recovery but to understand the rationale behind the procedures, the limits of each piece of equipment, and the trade-offs involved in choosing a recovery method. The tension between speed and safety is not a trivial concern; it is the fulcrum on which asset utilization balances. A well-trained crew can execute a double-tow with precision, minimizing the risk of compounding damage and ensuring that the second asset is deployed only when it truly adds value to the operation. Likewise, maintenance staff must cultivate a culture of proactive care, where early warning signals are treated as calls to action rather than excuses to delay. When fleets invest in this culture, the double-tow scenario ceases to be a mere problem and becomes a measurable driver of reliability, employee engagement, and customer confidence. The narrative shifts from regret over a breakdown to a disciplined, ongoing investment in the resilience of the entire recovery ecosystem.

In broader terms, the double-tow moment embodies a larger truth about asset-heavy industries. The image of a tow truck towing a tow truck is a compact allegory for systemic vulnerability—an emblem of how disruptions reveal the fragility and strength of a fleet’s design. The response to such disruptions—whether through spare capacity, predictive maintenance, or smarter dispatch—defines the difference between cascading failures and controlled resilience. When a fleet can weather the occurrence of a double-tow without sacrificing service levels, it earns a quiet competitive advantage grounded in reliability, predictability, and sustainable cost control. The chapter thus circles back to the core theme: assets must be managed not as isolated machines but as dynamic elements within an ecosystem that must anticipate, absorb, and adapt to failure. The double-tow scenario, once seen as an oddity, becomes a diagnostic tool and a catalyst for structural improvements that strengthen the entire operation. And as operations evolve, fleets that translate this insight into precise maintenance, robust training, and intelligent scheduling will not merely survive isolated incidents; they will redefine what it means to deliver rapid, dependable service in an asset-intensive industry. To explore related contexts where recovery planning and rapid response intersect with complex logistics, consider how airport emergency response operations handle recovery and redeployment of equipment under time pressure.

For a deeper, practical perspective on how such recovery protocols have evolved in time-critical environments, read about airport emergency rescue operations. This real-world context helps illuminate the choreography of multiple assets, risk management, and the continuous optimization mindset that underpins successful double-tow handling. airport emergency rescue operations.

External reference: for a concise, formal definition of a tow truck and its core function, see the standard dictionary entry. Merriam-Webster defines a tow truck as “a vehicle equipped with a mechanical apparatus for hoisting and pulling, used to tow wrecked, disabled, or stalled automobiles,” a definition that anchors the operational and economic discussions in this chapter. https://www.merriam-webster.com/dictionary/tow%20truck

Double Tow in the Real World: Safety, Regulation, and Skill in the Practice of Towing a Tow Truck

The sight of a tow truck pulling another tow truck is striking in its practicality and complexity. It is a maneuver born of necessity rather than routine, a solution crafted to move a broken, stalled, or damaged vehicle that cannot safely drive itself. In the towing industry, this double-tow arrangement sits at the intersection of mechanical prowess, risk management, and regulatory discipline. It demands a precise balance of power, control, and planning that goes far beyond the familiar one-vehicle recovery. When a scene unfolds on a highway shoulder or at a depot entrance, the second, running tow truck becomes a moving anchor for the disabled unit, and the stakes rise quickly: a misrigged connection, an overlooked weight distribution issue, or a momentary loss of situational awareness can turn a controlled recovery into a multi-vehicle incident.

The core of the operation rests on sound rigging and dependable equipment. The towing vehicle must be equipped with a winch strong enough to pull a second heavy machine or, more commonly, a specialized flatbed or lift system that can cradle the disabled truck without transferring damage. The operator must decide whether the right approach is a flatbed transfer—carrying the entire vehicle on a bed—or a controlled draw that relies on robust winches, tie-downs, and low-load transfer points. Either choice requires careful load calculations, a clear understanding of the disabled vehicle’s weight distribution, and a plan for maintaining control across moving parts of the chain of recovery. The weight of two heavy vehicles, the potential for sudden acceleration or deceleration, and the risk of a snag in a tether or strap all demand rigorous attention to detail before movement begins.

Beyond the mechanics lies a field where timing meets prudence. The double-tow scenario typically arises when ordinary driving abilities are insufficient to keep both vehicles safe. A breakdown might render a tow truck immobile but still mechanically unstable, or the damage from an incident might compromise steering, braking, or tire integrity. In such moments, the commander on the scene must choreograph a sequence that minimizes the risk of secondary harm to nearby motorists, pedestrians, or emergency responders. This choreography includes establishing a safe work zone, coordinating with traffic management, and ensuring that lighting and reflective gear are in place to counter low visibility. It also involves continuous communication with the driver of the towed unit, who must understand the planned path, speed limits, and the signs that indicate when and how the tow will begin and end. The operator’s ability to maintain a steady, controlled pace is as crucial as the mechanical integrity of the rigging.

Guidance and discipline in this domain have evolved in lockstep with the regulatory framework that governs modern recovery work. The introduction of national standards and procedures around high-risk towing operations has shifted much of the decision-making from improvised improvisation to codified practice. The newest act and its companion regulations have clarified roles, set performance benchmarks, and established a tiered certification process for operators who perform double-tow recoveries. The emphasis is not merely on being able to attach lines and drive straight; it is on understanding load transfer during dynamic conditions, knowing how to re-route a tow in response to weather or traffic, and being prepared to disengage and manage a safe stop if something slips out of alignment. These requirements acknowledge that the secondary vehicle is not just a passive weight but a critical component in a complex system of recovery that can fail if any single link—rigging, driver skill, or scene management—is weak.

Training, in particular, has become the fulcrum around which progress pivots. A proficient double-tow operator must go beyond a standard commercial license. They must demonstrate competence in advanced rigging, load distribution, and the practicalities of coordinating a recovery under pressure. Crisis management and scene safety are no longer afterthoughts; they are integral to the job, with explicit expectations around communication with law enforcement and first responders and a clear understanding of legal obligations when incidents unfold. The best responders practice with a mindset of redundancy: multiple ways to secure the towed vehicle, alternative routes for movement if the primary plan becomes untenable, and a systematic method to verify every device in the chain before movement. The field emphasizes preparing for the unforeseen—an anchor line that begins to slip, a connection that loosens, or a sudden gust of wind that tests the stability of the rig. In these moments, the operator’s calm, deliberate decision-making can be the difference between a controlled recovery and a cascading cascade of accidents.

Public safety sits at the pinnacle of this discussion. The rationale for stringent oversight is straightforward: a double-tow involves substantial mass, high forces, and the potential for considerable harm if containment fails. Community input has underscored this reality; a nationwide consultation conducted in the wake of regulatory reforms showed strong public support for enhanced oversight and transparency in towing operations. The regulations mandate real-time tracking of tow movements on crash scenes and require reporting of all towing activities. Such measures are not about surveillance for its own sake; they are tools to deter unsafe practices, hold operators to consistent standards, and provide accountability that motorists and first responders can trust. The public’s preference for visibility—knowing where a truck is, who is in control of the operation, and what procedures are being followed—reflects a broader demand for safety culture across the industry. By integrating rigorous inspection protocols, layered certifications, and explicit emergency response procedures, the regulatory framework aims to reduce the probability of avoidable mishaps while preserving the essential service that tow operators provide in the wake of incidents.

To translate these principles into practice on the ground, the industry has leaned on both formal standards and a shared sense of professional responsibility. Real-world recoveries demand not only robust equipment but also disciplined teamwork. The operator in control must be vigilant for signs of wear or misalignment in the rigging, and the crew around the scene must anticipate the evolving dynamics of a moving load. This is not a solitary task; it is a coordinated operation that calls for precise timing, clear signals, and a shared mental model among all participants—driver, spotter, dispatcher, and responding agencies. The goal is not merely to move a vehicle from point A to point B; it is to do so while preserving the integrity of the road system, protecting people, and sustaining the public’s trust in the professional standards that govern the service.

For readers seeking a practical entry point into the broader topic of incident response and the training that underpins it, a focused resource on emergency response training best practices can provide a useful perspective and actionable guidance that translate well to double-tow scenarios. This resource offers concrete steps for evaluating risk, layering controls, and practicing the critical communication that keeps teams aligned when pressures rise. It also reinforces the idea that preparation is inseparable from performance in the field.

As the industry continues to refine its approach to high-risk operations, the double-tow remains a compelling case study in how stringent standards, skilled hands, and thoughtful planning come together to convert a challenging recovery into a safe, efficient, and accountable service. The evolution of this practice mirrors the broader arc of towing as a profession: from a roadside fix-it task to a highly regulated, data-informed discipline that serves the public with reliability and care. In this context, the act of one tow truck pulling another becomes more than a mechanical solution; it is a testament to the discipline, training, and governance that make the road safer for everyone who shares it. For further authoritative information on the current standards and the legal framework guiding these operations, see the official regulatory publication on towing services. [External resource: https://www.transportation.gov/regulations/towing-services-act-2024]

Final thoughts

The practice of towing a tow truck among the broader spectrum of recovery work highlights a core truth: preparedness, precise equipment selection, and disciplined procedures determine both efficiency and safety. From mechanical failure to on-road accidents, dual-tow operations demand clear roles, robust winching configurations, and ongoing operator training. For Everyday Drivers, Residents & Commuters, Truck Owners, Auto Repair Shops & Dealerships, and Property Managers, the ability to anticipate challenges, stage the scene, and manage loads responsibly translates into reduced downtime, fewer secondary damages, and safer streets. The key takeaways are straightforward: verify readiness of both units, choose the appropriate winching setup, plan routes and traffic controls, document procedures, and stay compliant with local regulations. When these factors align, a tow truck towing a tow truck becomes not just a recovery maneuver but a measured, professional response that keeps communities moving.