When it comes to road assistance and transportation, having a reliable tow truck is invaluable. Whether you’re an everyday commuter needing quick emergency support, a truck owner looking to expand your service, or a property manager requiring prompt vehicle retrieval, understanding the costs associated with purchasing a tow truck is crucial. The prices can vary widely based on several factors, including the model, condition, brand, and features. This article will shed light on those variations, starting with an overview of tow truck pricing, exploring the factors that influence costs, and finally, breaking down the different types of tow trucks available on today’s market. By the end of this guide, you’ll be equipped with the knowledge needed to make an informed decision that fits your needs and budget.

Tow Truck Price Atlas: Reading the Market, Models, and the Real Investment Behind Every Tow

Prices are not just numbers on a spec sheet; they are reflections of the work a tow truck must perform, the reliability it must offer, and the risk a business owner is willing to absorb. If you are weighing the decision to buy a tow truck, you are balancing an appetite for prompt response and a budget that must survive the long haul of maintenance, insurance, fuel, and downtime. The question—how much does it cost to buy a tow truck—opens a broader conversation about value, feasibility, and strategic fit. The cost landscape is multi-layered. It begins with the basic type of truck, then moves through size and capacity, into condition and age, and finally into the realm of specialized equipment and upfits. Each choice carries not only a price tag but a different operating profile, a distinct maintenance path, and a separate potential for return on investment. In practical terms, buyers are choosing among a spectrum that stretches from compact, light-duty wheel-lift units to heavy, specialized rotators designed for complex wreck scenes. The most affordable option tends to be a smaller, simpler wheel-lift or flatbed that can handle routine roadside interventions and minor tows. The most expensive category sits at the top end of the market, where rotators combine heavy lifting with rotating capabilities, enabling the operator to recover and right vehicles in challenging positions. The pricing reality is that a typical used or lightly equipped model can be found in the lower tens of thousands, while a new or highly capable unit can push well past six figures. The spread exists not only because of the model type but also because of the configuration and the intended application. A light-duty wheel-lift, purchased used, may sit near the lower end of the range, while a new or highly equipped flatbed can hover in the mid-to-upper range. A rotator, given its specialized engineering and the demands of high-stakes recoveries, sits toward the far end of the spectrum. A clear takeaway emerges: the cost to buy a tow truck is a function of purpose. If your operations revolve around quick roadside assistance in a compact service area, you will gravitate toward a leaner, less expensive setup that prioritizes speed, ease of use, and fuel efficiency. If your business aspires to handle complex recoveries, you will need to invest in more capable machinery, greater stability, and more sophisticated control systems. Those capabilities have a price, but they also unlock a broader revenue potential and a higher response resilience in demanding environments. Another factor to consider is the condition and the age of the vehicle. A newer truck might carry higher initial costs, but it could yield lower long-term maintenance expenses and a longer period of dependable service before major capital expenditure is required. An older truck, while cheaper upfront, may require more frequent repairs and more downtime, which can erode profitability if not carefully managed. In practice, the decision becomes a balancing act between upfront expenditure and ongoing operating costs. This is where the concept of total cost of ownership (TCO) becomes essential. TCO looks beyond the sticker price to include insurance, license, maintenance, parts replacement, tires, fuel, and the cost of downtime when the vehicle is out of service. A prudent buyer will quantify these ongoing costs, compare them across options, and map them against projected utilization and revenue. For instance, if a more expensive, well-equipped truck reduces downtime and speeds the turnaround in tow operations, that efficiency can translate into more calls completed per shift, a higher daily revenue, and a faster path to profitability. Conversely, if the same investment sits idle in a yard due to insufficient demand or poorly targeted marketing, the higher monthly payments may not be justified. Financing considerations add another layer to the decision. Some buyers finance through commercial loans, other arrangements rely on dealer financing, while others may opt for owner financing or seller financing. The availability and terms of financing are influenced by credit conditions, the buyer’s business plan, and the expected utilization of the tow truck. Interest rates, down payments, and repayment schedules all affect the final cost of the vehicle over its life. A well-structured plan may include a phased purchase, starting with a smaller unit to establish operations and cash flow, followed by a later upgrade as the business scales and demand grows. It is also important to recognize that the initial price is just one part of the equation. The cost of ownership includes ongoing expenses that can surprise new entrants to the market. Insurance is a fixed cost that rises with vehicle value and risk exposure. Towing operations involve risks, and coverage must be adequate to protect against property damage, bodily injury, and environmental concerns. Maintenance costs accumulate as the vehicle ages, with wear items like brake pads, tires, hydraulics, and hydraulic fluid requiring regular attention. Fuel economy is another practical consideration; while modern fleets strive for efficiency, heavier-duty trucks with larger engines consume more fuel, impacting daily operating costs. Storage is a logistical cost too. Tow trucks require secure, accessible space, and the cost of parking or yard space should be included in the business plan, particularly for operators managing multiple units. In short, the price tag of a tow truck is the visible portion of a larger financial story. It is not merely about buying a chassis and a bed; it is about committing to a toolset that will anchor the service’s reliability, safety, and market competitiveness over years. The best approach to pricing, then, is to begin with a clear understanding of the service profile you intend to deliver, then translate that profile into a technical specification that aligns with anticipated demand and revenue. This process often involves a careful appraisal of the types of emergencies you are most likely to encounter, the typical towing distances, the types of vehicles you will encounter, and the environmental conditions in which you will operate. It also involves a realistic assessment of your workforce, as the crew’s skill set will determine how effectively the equipment is utilized, which in turn affects the overall cost of service and the rate at which you recover the initial investment. When evaluating options, it can be helpful to consult current listings on platforms that reflect the market in real time. Such listings provide a snapshot of what buyers are paying for specific configurations, age ranges, and equipment packages. They can illuminate price expectations and help you set a realistic budget based on verified, actual deals rather than speculative estimates. For those seeking more detailed current estimates and model-specific prices, the broader pricing overview on our site discusses the general ranges and the factors that push prices up or down. You can explore the general pricing landscape in our main guide: how-much-is-a-tow-truck. This reference serves as a general compass, not a replacement for due diligence, as the actual price you experience will depend on the specifics of your intended use and the market you operate within. As you plan, remember that the ultimate objective is not to pick the lowest price, but to secure a vehicle that aligns with your service goals, delivers operational reliability, and fits within the cash flow you can sustain. The decision should balance upfront cost against long-term value, considering maintenance outlook, downtime risk, and the potential to expand services as demand grows. With a clear plan and a realistic budget, you can avoid common pitfalls—overpaying for a feature you do not need, underestimating maintenance, or misjudging the market demand that will determine how quickly you recoup the investment. For readers who want a practical, current snapshot of pricing and model availability, a useful starting point is to browse the current listings on reputable platforms. This hands-on exposure complements the theory of cost by showing real-world examples, typical configurations, and the negotiation space that exists between buyers and sellers. It is also a reminder that the market is dynamic; what is affordable today may change tomorrow as demand evolves and supply tightens or relaxes. If you are planning to pursue a purchase, keep your eyes on the broader market signals—fleet needs, insurance costs, financing terms, and maintenance forecasts—because the decision is a strategic one that reaches beyond the sticker price. Finally, remember that the value of a tow truck is ultimately measured by how reliably it helps you meet the needs of your customers while sustaining a healthy margin for your business. The initial price tag is just the gateway to a broader operational capability; the real question is how well that capability integrates with your service model, how consistently it performs on demanding jobs, and how efficiently you can maintain it for years to come. For those who want a broader sense of what the market is doing today, the price ranges discussed above are reinforced by current listings and can serve as a practical guide as you begin a formal purchase process. As you move from curiosity to commitment, you may discover that the best choice is not the most expensive or the cheapest, but the option that best aligns with your service goals, your geographic coverage, and your long-term financial plan. External resource: https://www.ebay.com/itm/114879536733

null

null

From Flats to Rotators: A Practical Guide to Tow Truck Varieties and Their Price Tags for Your Towing Business

Choosing the right tow truck is more than picking a vehicle with a lift. It is a strategic decision that shapes the range of jobs you can take, the speed with which you deploy, and the cost efficiency you achieve day after day. In a market where capability and reliability directly translate into revenue, understanding how the different tow truck types align with your service mix—and what they cost to buy and own—becomes essential. This chapter weaves together the core distinctions among tow truck configurations with the real-world price ranges you’ll encounter in most practical purchases. It moves beyond mere sticker prices to consider how each type matches operational needs, the tradeoffs you accept for flexibility, and the long-term implications for your business’s cash flow, maintenance, and growth trajectory. In doing so, it remains tightly tethered to the central question of this article: how much does it cost to buy a tow truck, and what should you expect to invest to secure a unit that truly serves your business today and your plans for tomorrow.

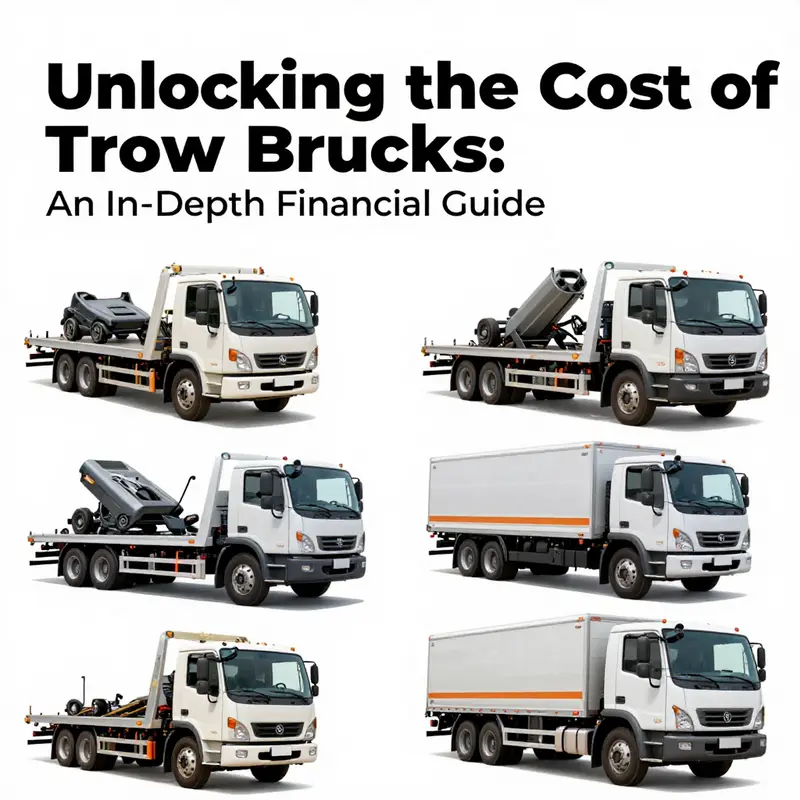

The first truth to grasp is that the towing sector spans a spectrum from simple, economical tools to highly specialized machines built to handle the harshest recovery tasks. The most basic, conventional tow trucks—often referred to as hook-and-chain systems—were among the earliest designs and still perform basic towing tasks with a minimal footprint. When priced for purchase, these conventional units typically sit at the lower end of the spectrum. If you are creating a shop that handles straightforward roadside recoveries or light-duty tows, a conventional configuration can offer a serviceable starting point without committing a large portion of capital to equipment you may not immediately need. The tradeoff, of course, is flexibility. A hook-and-chain system places constraints on vehicle handling and can pose risks to the towed vehicle’s underbody if used improperly. But for operations that value cost-effectiveness and simplicity, these units remain a viable option in the right context.

Beyond the most basic design, hydraulic tow trucks introduce a level of control and safety that translates into broader service capabilities. With a hydraulically operated boom, these units offer smoother lifting and precise placement of the vehicle onto the truck bed. They are generally more forgiving in heavy or awkward recoveries and can reduce the risk of collateral damage to the towed vehicle. The price point for hydraulic units sits higher than traditional hook-and-chain configurations, reflecting the added complexity and the broader range of tasks they can handle. If your service mix includes frequent on-scene lifts, tilting the vehicle onto the bed, or transporting cars that require careful handling, a hydraulic setup is typically a more efficient long-term investment than a purely conventional rig.

Flatbed tow trucks, however, represent a distinct philosophy of towing. Rather than dragging the vehicle onto a bed, a flatbed transports the entire car on a level surface. This design is especially attractive when the client roster includes luxury vehicles, low-clearance sports cars, or vehicles that are already severely damaged. By keeping the towed vehicle off the roadway and away from the truck’s chassis, flatbeds minimize the risk of additional damage during transport. They also simplify loading when wheel alignment or drive-train integrity is a concern. The price for flatbed configurations tends to be the most pronounced among common tow truck types, reflecting their engineering sophistication and the range of use cases they cover. You should anticipate paying a premium that aligns with the added capabilities a flatbed provides, and you should plan for higher initial investment as well as potentially higher ongoing maintenance costs. In many fleets, flatbeds are the backbone for long-haul tows and for operations that promise higher-margin jobs due to the ability to handle a wider variety of vehicles with confidence.

Wheel-lift tow trucks sit in a middle ground between the simplicity of hook-and-chain units and the comprehensive capabilities of hydraulic and flatbed configurations. A wheel-lift system raises one end of the vehicle by the wheels while the other end remains in contact with the ground, offering a blend of cost efficiency and versatility. For many operators, wheel-lift units are the workhorse of daily towing and roadside service. They can handle a broad array of vehicle types without the full expense of a flatbed, and they typically present a favorable balance between upfront cost and ongoing operating expenses. When evaluating price, wheel-lift trucks tend to fall between conventional and flatbed models, often delivering substantial capability without the outsized price tag associated with a premium flatbed setup. If your business model centers on quick detach and move operations, or on volume work where cost per tow matters, wheel-lift can be an especially compelling choice.

Rotator tow trucks and integrated, single-unit systems sit at the far end of the capability spectrum—and, correspondingly, at the high end of the price spectrum. Rotators feature a heavy rotating hydraulic crane that can lift and rotate vehicles at elevated angles, a capability that is invaluable for complex recoveries, impound jobs, and high-difficulty incidents. Integrated units, which blend the recovery apparatus into a single, robust machine, maximize strength and stability for the harshest conditions. The performance demands of these machines are matched by their price tags, which frequently exceed the mid-six-figure mark and can extend well beyond. These rigs are not merely about lifting power; they are about on-scene reliability, safety under demanding conditions, and the ability to complete challenging recoveries with minimal additional support. For operations that secure a high volume of difficult recoveries—such as accident scene management or heavy-duty roadside incidents—rotators and integrated units can pay off through improved first-attempt recovery success, reduced on-scene time, and broader service capabilities.

If you zoom out from specific configurations to the market as a whole, you’ll see a price ladder that generally elevates with capability, build quality, and capacity. Conventional units sit toward the lower end, flatbeds and hydraulic designs occupy the middle range, and rotators or integrated heavy-duty systems anchor the top. In numerical terms, conventional tow trucks commonly fall in the neighborhood of roughly $30,000 to $50,000 for older, basic versions, sometimes dipping lower when condition and mileage are favorable. Flatbed tow trucks—owing to their stronger engineering and broader functionality—tend to command prices from about $80,000 to over $150,000, with the higher end reserved for newer models, larger bodies, longer beds, and advanced control systems. Wheel-lift configurations often land between these two extremes, with typical pricing spanning the $40,000 to $90,000 range, depending on capacity, highway efficiency, and whether the unit is older or more recently refurbished. Rotator and integrated units sit at the upper end, often stretching from $150,000 and up, driven by the heavy-duty lifting hardware, the crane’s reach and rotation capabilities, and the overall durability required in demanding environments.

These ranges reflect the market’s variability and the wide spectrum of use cases. They also underscore the importance of aligning a purchase with your anticipated workload. If your dispatch volume is modest and you’re serving a narrow geographic area with primarily light-duty tows, a conventional or wheel-lift setup could meet your needs at a modest price. If your business targets a mix of damaged-vehicle transport, luxury-car recovery, and on-scene management under tighter timelines, a hydraulic or flatbed design might deliver better return on investment by enabling safer, faster, and broader service coverage. If you anticipate encountering the most challenging recoveries—stalled vehicles in precarious spots, multi-vehicle incidents, or situations requiring precise control and substantial lifting power—a rotator or integrated unit could provide the reliability you need, even if it comes with a heavier capital outlay.

Another reality behind the price tags is the importance of the engine and chassis, the optional equipment, and the overall footprint of the unit. The powertrain and chassis determine not only the truck’s towing capacity but also fuel efficiency, maintenance intervals, and the ability to operate profitably across long shifts or in dense urban routes. A higher-performing engine and more robust chassis can translate into fewer breakdowns during critical jobs, which, in turn, reduces downtime and the cost per tow. Optional equipment—such as larger winches, extended booms, additional wheel-lift capacity, integrated lighting, on-board winches for wheel removal, or extra storage and tool compartments—can push prices higher, but these upgrades often pay for themselves in faster response times and safer operations.

Given these dynamics, it is essential to approach the decision with a clear picture of your business model and your expected service mix. If your operation emphasizes rapid response across a broad service area with a steady stream of light to mid-weight tows, a mid-range hydraulic or wheel-lift setup may provide the best balance of upfront cost and ongoing operating efficiency. If your plan includes court-side or impound work, specialized recoveries, and a need to transport high-value vehicles with utmost care, investing in a flatbed with high-quality components would likely yield greater reliability and customer satisfaction over time. For the toughest recoveries, where on-scene safety and controlled lifting are non-negotiable, a rotator or integrated unit can be the strategic asset that distinguishes your business from competitors who can only offer standard towing.

The decision, however, does not end with choosing a configuration. It also requires a thoughtful consideration of whether to purchase new or used, and how to structure the financing and maintenance plan. A new unit carries the appeal of warranty coverage, the latest technology, and the confidence that comes with a clean slate. But it comes at a premium price that can strain cash flow, especially for startups or small fleets. A well-maintained used unit can deliver substantial savings, and many buyers find that a carefully inspected pre-owned machine with documented maintenance history can meet the needs of a growing business for a fraction of the cost of a new model. The risk with used units lies in hidden wear, potential component fatigue, or the need for early major maintenance—factors that can erode the savings if not properly managed. A robust due diligence process—inspection by a qualified technician, review of service records, and a thorough test of all critical systems—can mitigate these risks and reveal good value in the used market.

Beyond the purchase price, you must forecast the total cost of ownership. Financing terms, insurance premiums, license and registration, fuel economy, maintenance schedules, tire wear, and potential downtime all color the bottom line. A unit that appears affordable upfront may accrue higher monthly costs if it consumes more fuel, requires expensive repairs, or necessitates frequent downtime for service. Conversely, a slightly higher upfront investment in a well-maintained, modern unit with efficient components can reduce operating costs and extend the time between major overhauls. Many operators find it prudent to model scenarios that compare, side by side, a conservative plan based on a basic, economical unit against a more capable model that carries higher initial costs but delivers faster response times, broader service capabilities, and reduced risk during complex recoveries. The math isn’t purely about the sticker price; it’s about the lifetime value of the asset and how much revenue the asset helps you capture over its years of service.

For readers who want to anchor these considerations to real-world price expectations, it can be helpful to start with a quick reference frame. An at-a-glance sense of the typical starting prices across major tow truck types gives you a baseline from which to negotiate on features and condition. If you want a quick snapshot of typical sticker prices, see how-much-is-a-tow-truck. This internal link provides a concise overview that you can consult as you compare options with suppliers and dealers. It isn’t a substitute for a detailed assessment of each unit’s condition, but it helps you frame the conversation and set realistic expectations as you solicit bids and review specifications. When you’re ready to go deeper into industry standards and guidelines that govern safety, performance, and interoperability, the broader landscape becomes your next reference point. The Tow Truck Association’s official site offers a comprehensive look at standards and best practices that inform how manufacturers engineer these machines, how operators should maintain them, and how fleets can approach training and safety in a way that aligns with regulatory expectations.

In practice, the process of selecting a tow truck begins with a careful mapping of job types and expected workloads. If your service area includes a high volume of heavy-duty tows—highways, commercial fleets, or incident response—you may need to think beyond basic mobility and toward a platform that can endure long hours with reliable uptime. If punctuality and damage prevention are paramount, you will likely prioritize flatbed or hydraulic designs with proven durability and a robust maintenance ecosystem. In contrast, if your plan is to maximize job coverage with a lean staff and a limited fleet, you might place greater weight on the speed and flexibility of a wheel-lift configuration, balancing upfront cost against the ability to handle a broad spectrum of routine tows without requiring multiple specialized units.

The customer ecosystem also matters. Proximity to repair facilities, the typical weight and dimensions of vehicles you most commonly handle, and the kinds of emergency responses you anticipate will influence your configuration choice. For instance, a shop that frequently supports roadside assistance along a dense corridor may benefit from a lighter, nimble wheel-lift or hydraulic unit that can maneuver quickly and tows a broad mix of domestic and foreign vehicles with minimal setup time. A shop that serves a dealership network or specializes in damaged-vehicle transport may gain more value from a flatbed’s protection against body damage and its ability to carry vehicles with atypical frames or bumper configurations. Where you situate your fleet in relation to service areas can also affect operating costs. A unit with a longer reach and better on-board capabilities reduces the need for additional equipment on scene, which translates into fewer trip charges for customers and more predictable dispatch performance for your operation.

As you finalize a purchase plan, inventory quiet diligence into the market signals that influence pricing becomes essential. The pool of used units, the timing of market refreshes by manufacturers, and the availability of certified pre-owned equipment all shape how you time a purchase and negotiate terms. Dealers often present a menu of configurations that reflect both current demand and anticipated regulative or safety updates. For buyers, this creates both opportunity and risk. The opportunity lies in finding a well-maintained unit that meets or exceeds your operational requirements at a compelling price. The risk arises when a unit’s condition obscures underlying issues that could shorten its service life or introduce unexpected downtime. A structured inspection routine—covering engine, transmission, braking, lifting mechanisms, winches, hydraulics, and electrical systems—helps you separate the signal from the noise in used-market deals and guards against expensive surprises after you bring the unit home.

In the end, deciding how much to invest in a tow truck comes down to aligning capability, reliability, and total cost of ownership with your business plan. The price you pay is a mirror of the value you expect the truck to deliver over its operational life. A lower upfront cost can be attractive, but it must be weighed against potential higher maintenance, reduced on-scene performance, and limited service scope. A higher upfront price can yield greater on-site capability, efficiency, and resilience, but only if the business case supports those benefits. The best choice is one that translates into more time on the road performing jobs, fewer downtimes in the shop, and a clear path toward growth—without exposing your business to financial strain. As you navigate the pricing landscape, keep your eyes on the long game: return on investment, reliability on the road, and the capacity to expand your service footprint without sacrificing quality or safety.

For a concise primer on pricing context before you begin shopping, you can reference general price ranges for the core configurations. These figures are broad, intended to guide initial budgeting and negotiation expectations rather than serve as a precise quote for any given unit. Conventional trucks often present the most affordable entry point, with a typical range that makes them accessible to startups and small fleets. Flatbed and hydraulic variants command higher prices, reflecting their broader capabilities and the value they deliver in protecting client vehicles and enabling a wider array of recoveries. Wheel-lift units occupy a middle ground, offering robust performance without the substantial premium of a full flatbed or rotator. And when extreme recoveries and high-torque lifting come into play, rotators and integrated systems push the ceiling higher still, delivering top-tier capability at a premium price. These generalities should be validated against live listings and dealer inventories as you refine your budget and procurement timeline.

One practical approach to budgeting is to parallel the purchase with a staged deployment plan. For a brand-new startup with a modest daily volume, you could begin with a mid-range hydraulic or wheel-lift unit and reserve capital for additional equipment or a second unit as demand scales. For a growing operation with anticipated expansion into heavier work, a used-but-well-maintained flatbed or a newer hydraulic unit could represent a balanced mix of reliability and capability, with a clear maintenance plan to minimize downtime. For mature fleets that require top-tier performance and incident-ready strength, investing in a rotator or an integrated heavy-duty model becomes not a luxury but a strategic necessity, provided the business metrics justify the expense through higher utilization and a broader service offering.

Independent of the configuration you choose, the price of admission to the towing market is not just the sticker price. It includes the ongoing costs of ownership—the fuel bill, insurance premiums, maintenance and repairs, tires, and possible financing charges. These ongoing costs determine how quickly the asset pays for itself. A unit with excellent uptime, low repair frequency, and strong resale value will deliver a lower total cost of ownership over its life and, by extension, a stronger profit margin per tow. Conversely, a machine that requires more frequent downtime or that carries high maintenance burdens may erode profitability even if its initial price tag is modest. This is why a rigorous total-cost-of-ownership analysis, conducted with realistic utilization projections and maintenance schedules, is essential before you place any purchase order.

The landscape of tow truck pricing is indeed broad, and that breadth is a resource for thoughtful buyers. Rather than chasing the lowest price or the most expensive unit, the intelligent path is to define your service profile—the typical vehicle types you’ll encounter, the conditions on which you’ll operate, and the speed at which you expect to satisfy customers—and then seek the configuration that delivers the best alignment between capability and cost over the next several years. In this context, price becomes a signal about the expected value a given unit will unlock for your business, rather than a standalone metric. The right choice will be the one that supports quicker, safer recoveries; calmer, more predictable dispatch operations; and a durable platform that can evolve with your growth plans. It’s not simply about buying a tow truck; it’s about selecting a strategic asset that underpins your ability to serve customers reliably and expand into new service territories with confidence.

For readers who want to dive deeper into current models, pricing trends, and technical specifications that inform these decisions, you can consult industry summaries and dealer catalogs. And when you are ready to validate the broader standards that govern safety and performance, you’ll find the field’s best practices codified by professional bodies. For a broader industry reference about standards and guidelines, you can visit The Tow Truck Association’s official site. This external resource provides a comprehensive framework that helps buyers and operators understand safety, maintenance, and training expectations across the sector. In the meantime, keep the core question in focus: what price range best fits your business goals, your expected workload, and your plan for growth? By mapping your operational needs to the construction and capability of the truck, you’ll arrive at a choice that is not only affordable but also strategically sound.

To summarize, the market offers a spectrum of tow trucks from economical conventional hooks to advanced rotators. Price ranges are broadly defined by the unit’s capacity, durability, and the breadth of its on-scene capabilities. Conventional units remain the least expensive option, while flatbeds and hydraulic systems represent a middle-to-high tier with substantial value for protecting vehicles and expanding service capability. Wheel-lift units offer a compelling balance of cost and versatility, and rotator or integrated units sit at the top of the scale, aligning with operations that demand maximum on-scene capability and fastest possible recoveries. The actual decision hinges on your business’s workload profile, your proximity to reliable maintenance channels, and your tolerance for upfront investment versus long-term operating costs. By anchoring your planning in these realities and using the market as a guide, you can approach the purchase with clarity, confidence, and a clear path to sustainable profitability. If you want to supplement this narrative with current price specifics as you shop, remember to treat price as a guide rather than a fixed limit—there is always room to negotiate, upgrade, or tailor equipment packages to fit your budget and your business objectives.

External resource reference: For industry standards and guidelines that underpin safety and performance in tow truck operations, consult The Tow Truck Association’s official site at https://www.towtruckassociation.org.

Internal link reference: For a quick reference on typical price points and to stimulate planning discussions with suppliers, explore the overview at how-much-is-a-tow-truck.

Final thoughts

Purchasing a tow truck can be a significant investment, influenced by numerous factors including model, condition, and specialized features. Understanding the various price ranges and operational capabilities of different types of tow trucks is essential for making an informed decision. Whether you are a vehicle owner, a business in need of towing capabilities, or a property manager, identifying the right tow truck that meets your requirements and budget will ensure that you have the necessary assistance at your fingertips. As you navigate the purchasing process, keep in mind not just the initial investment but also the long-term benefits and operational costs associated with each type of tow truck.