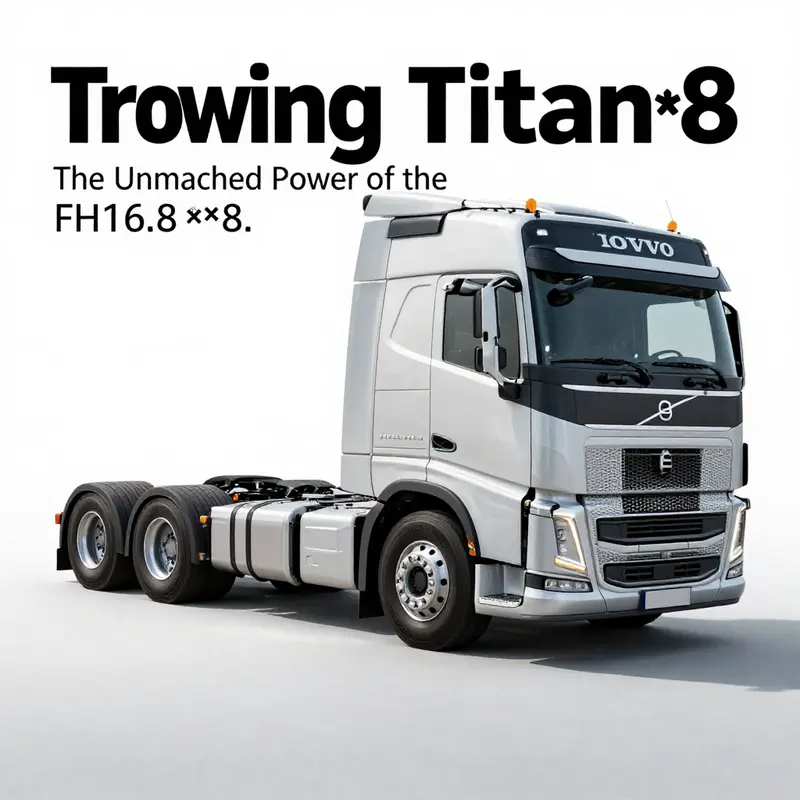

Understanding towing capacity is crucial for everyday drivers, truck owners, and businesses that rely on heavy hauling. At the forefront of this capability is the Volvo FH16.8×8, boasting an incredible towing capacity of 912 tons. This capacity positions it as a leader among heavy-duty trucks, far surpassing typical models like the British Iveco X-Way and the Peterbilt wrecker, which both handle up to 100 tons. The unique design and advanced technology behind the FH16.8×8 are key to its impressive performance. Our first chapter will provide an in-depth overview of this remarkable truck, followed by a comparative analysis with its closest competitors, showcasing how the Volvo maintains its lead. Finally, we will explore the technological innovations that enable such extraordinary towing capacities, providing insights for residents, commuters, and fleet managers alike.

Tow Power in the Real World: From Ultra-Heavy Haulers to an Electric Pickup, and What It Means for the Capacity Question

Towing capacity is more than a single number on a spec sheet. It is a conversation about how weight, momentum, braking, and stability interact on real roads, and about how a vehicle’s purpose shapes the ceiling of what it can legally and safely move. When people ask which truck has the highest towing capacity, they are often drawn to dramatic end points. Among the data that circulate in specialized freight and heavy-haul circles, there exist figures that sit on almost mythic extremes: an eight-axle European tractor unit designed for industrial and military-scale tasks, built to move loads that dwarf everyday trailers. In contrast, the everyday heavy-duty class—multi-axle wreckers and similar configurations—lands in a very different neighborhood, commonly cited in the tens or, at most, low hundreds of tons. Between these poles sits a new frontier: the electrified, consumer-focused pickup that, by virtue of instant torque and modern traction control, can shunt respectable loads but within a framework that emphasizes efficiency and urban practicality. The spectrum is wide, and the interpretation of “highest” shifts with the lens you bring to the table: vehicle category, intended use, and how “towing capacity” is defined in the first place.

To start with the far end of the spectrum, consider a class of vehicles engineered for extremes. In the published data, there exists a tractor configuration with an eight-axle setup and a heavy-duty frame built for stability under enormous tension. The figure commonly cited for maximum towing capability in that niche is staggering: a capacity on the order of hundreds of tons, with official load ratings that push past 900 tons in some documented scenarios. Such numbers are not everyday towing figures. They belong to specialized heavy-haul operations, where the environment—long, controlled routes, dedicated escorts, and limited access roads—allows this kind of extreme payload. In the same realm, there are other multi-axle systems capable of transporting around 100 tons, sometimes in civilian contexts and sometimes in closely regulated industrial operations. A separate class exists for military transport, where a heavy tank-transporter design can haul up to two hundred tons. Taken together, these figures illuminate a scale far beyond standard consumer or light-commercial towing. They illustrate a set of engineering priorities aimed at sheer bulk, stability under extreme load distribution, and the ability to survive dynamic forces when a massive trailer is swayed or braked aggressively. It is a stark reminder that “towing capacity” is not an absolute ceiling for all trucks, but a category that morphs with purpose, regulation, and the nature of the requested task.

On the other hand, a different part of the landscape demonstrates how far the field has progressed into more practical, road-going capabilities. In the current market, a fully electric pickup model from a contemporary producer has emerged as a leading option in the sub-urban to rural heavy-tow segment. It touts a towing capacity in the neighborhood of twenty thousand pounds when properly equipped with the necessary towing package and trailer hitch. To put that into perspective, twenty thousand pounds is about ten short tons, a figure that sits comfortably within the demands of large utility trailers, boats, and construction equipment transport—yet it remains a far cry from the colossal loads discussed in the ultra-heavy-haul category. What makes this figure notable is less the raw mass than the combination of torque availability, inverter management, and advanced chassis engineering that makes it feel strong in practice. The dual-motor arrangement delivers substantial torque from a standstill, which translates into real-world pull when the trailer is first engaged. This is not merely about raw horsepower; it is about the instantaneous control of torque, the ability to manage traction on slippery ramps or wet pavement, and the confidence that the drive system will respond predictably under load.

The architecture behind the electric option centers on three pillars that together determine towing performance. First, the powertrain must deliver ample low-end torque. This is what enables a heavy trailer to bite into the road without stalling or excessive wheel spin, even from a standstill. Second, the chassis and frame must be reinforced, with weight distribution that keeps the rig stable when the hitch is pulling in a way that shifts the trailer’s center of gravity. Third, a suite of towing technologies—an integrated trailer brake controller, braking assist, and enhanced cooling systems for both battery and motors—ensures that the vehicle can sustain a heavy load through longer pulls and varied climates. These features reflect a broader shift in the industry: electrification is expanding the toolkit for towing, not merely by increasing raw power but by enabling more precise, controllable, and reliable operation under load. In this sense, the latest electric configuration is not a smaller version of the same idea; it is a reimagined approach to how towing is managed at the vehicle level, with software, thermal design, and traction control playing as much a role as leaf springs and axles.

To be sure, the electric option still sits within a framework that many readers will recognize. It targets individuals and fleets that need to move large trailers or equipment, whether for work sites, recreational trips, or light industrial transfer. The approach is pragmatic: you choose the package that supports the hitch and trailer you intend to use, you verify the braking and cooling systems are sized for the job, and you accept that the payload and towing figures operate within ranges that reflect efficiency goals and warranty boundaries. The interplay of weight, dynamics, and control systems means that the capability you experience in practice may hinge as much on the trailer you attach as on the vehicle you pull it with. In other words, the 20,000-pound figure is not an absolute limit you can test in a vacuum; it is a measured result within a system designed to handle that load safely and consistently, with contingencies for temperature, battery health, and battery-state-of-charge at the start of the tow.

This contrast between the extreme, purpose-built haulers and the more commonplace, road-ready platforms helps explain why “highest” can be misleading if taken as a single universal yardstick. The big, multi-axle, high-load machines show what is technically possible when the mission is to move as much as humanly and mechanically feasible—often on private roads or controlled lanes with special permissions. The electric pickup represents what is practical for daily life, where accessibility, efficiency, and urban compatibility become important. What unites these machines, beyond their ability to haul, is a shared reliance on an integrated system: the trailer, the hitch, the braking interface, the suspension, and the way the vehicle’s electronics coordinate to deliver control rather than mere mass. In that sense, the story of towing capacity is really a story about system design and the needs of the operator, not about any single number. It is a narrative that shifts as the vehicle class and the intended application shift, and it is a reminder that the market continues to evolve in ways that expand what “towing capacity” can mean in the real world.

For readers who want a grounded sense of how towing figures translate into real-world decisions, consider how a typical user evaluates capability. The first question is often about what is being towed and where. A family planning a weekend with a large trailer may prioritize hitch compatibility, stability, and the ease of maneuvering with a heavy load in variable weather. A contractor moving equipment between sites will weigh payload, range, and the ability to re-charge at a job site or a remote location. A fleet operator, balancing maintenance costs, uptime, and serviceability, will weigh peak capabilities against duty cycles and reliability. In all cases, the goal is not merely to exceed a number; it is about delivering a predictable, controlled towing experience that aligns with the vehicle’s overall design philosophy. And in that sense, the question of which truck has the highest towing capacity is best answered not by naming a champion but by understanding where each candidate sits on a spectrum of purpose-built capability and practical utility.

To connect these ideas with practical steps, buyers and planners can use a simple framework when evaluating towing needs. First, define the heaviest load you will regularly tow, including the trailer’s gross weight and any payloads you carry on the trailer itself. Second, assess the driving environment: highway miles, grade, temperature ranges, and expected operating hours where the vehicle will haul. Third, confirm that the vehicle’s towing package includes all the necessary calibrations and safety features, such as trailer brake integration, weight-distribution controls, and sensors that monitor tire load and brake temperatures. Fourth, compare power delivery characteristics. A system that can deliver strong low-end torque, stable high-end torque, and robust thermal management will typically perform better under sustained towing than a system tuned for peak horsepower alone. Fifth, consider the broader ecosystem: charging options for electric models, maintenance cycles for heavy-haul configurations, and the availability of support and parts in your region. In this broader view, the most capable choice is the one that harmonizes the task with the vehicle’s design philosophy, rather than the one that simply pushes the largest raw number.

For those curious about how this translates to everyday decisions, a useful point of reference is the practical guide to understanding a truck’s towing capacity in common terms. It walks through how to assess what a given vehicle can tow in real-world conditions and how to prepare for a tow with an appropriate hitch, wiring, and braking setup. You can explore this practical overview here: how much can my truck tow?. The guide emphasizes the need to match equipment to task, to account for trailer dynamics, and to ensure that all safety systems are engaged and properly calibrated before departure. It also underscores the reality that the best choice for a given scenario is a balance of capability, reliability, efficiency, and cost of ownership, rather than a single record-breaking figure.

As the market continues to evolve, the story of towing capacity will increasingly hinge on the convergence of heavy-haul engineering and electrified propulsion. The ultra-heavy tractor and the rugged, road-ready electric pickup sit on opposite ends of the spectrum, yet both illustrate how modern trucks are shaped by broader priorities: safety, control, and the ability to move weight with confidence. The heavy-haul class shows what is possible when the mission demands it—an engineering feat that relies on an orchestration of multiple axles, precise load-bearing elements, and highly specialized regulatory accommodations. The electric pickup, meanwhile, demonstrates how electrification can redefine the user experience by injecting torque where you need it most, offering smart torque management and thermal resilience that support stable towing performance even as the battery pack bears the energy load of a heavy trailer. Between these two worlds lies a healthy reminder: the right tow capacity is the one that fits the job, not the one that seems most impressive in isolation. In the chapters to come, we will continue to explore how different vehicle architectures shape towing behavior, what their limitations look like in real operation, and how users can navigate the trade-offs between peak capability and everyday practicality. The progression is clear: as vehicle technology advances, so too do the standards by which we measure the value of that capability, and so the art of choosing a tow-ready vehicle becomes an exercise in understanding both the physics of weight transfer and the realities of road use.

External reference: https://www.ford.com/trucks/f-150-lightning/

Extreme Tow Ratings Unveiled: Which Truck Tops the Towing Capacity Charts

Understanding the Peak of Towing Power

Towing capacity is often discussed in terms of pickups and medium-duty rigs. Yet the true extremes live in a specialized class of heavy haulage equipment. These machines are engineered to move thousands of tons when needed. Comparing their capabilities requires looking beyond simple numbers. It requires understanding what those numbers mean, how they are achieved, and the limits imposed by design, law, and infrastructure. The most capable conventional tractor unit in the available data is a specialized heavy tractor configured with multiple drive axles and support axles, rated to tow roughly nine hundred and twelve tons under controlled conditions. That figure dwarfs the next tiers of heavy-duty commercial towing, which range from roughly one hundred to two hundred tons in purpose-built wreckers and military transporters.

At first glance, a 912-ton rating seems almost mythical. It arises from an optimized combination of heavy chassis, massive torque, advanced transmissions, and a robust accessory set. These trucks use high-ratio gearing to convert engine output into usable pulling force at low speeds. They rely on multi-axle configurations to spread load and improve traction. Cooling systems and braking packages are oversized to handle sustained, high-load operations. The result is a vehicle capable of hauling exceptionally heavy cargo on suitable trailers or moving derailed rolling stock and other exceptionally heavy objects on public roads with the right permits.

Comparative numbers can mislead without context. A commercial six-axle wrecker rated at one hundred tons is designed for vehicle recovery and roadside service. It has specialized pulling gear, outriggers, and winches built for extraction. A heavy 8×4 tractor unit with a projected capacity near one hundred tons focuses on modular transport scenarios, coupling to heavy lowbed trailers or heavy-duty dollies. A dedicated military tank transporter, built for armored loads, may list capacities around two hundred tons. That vehicle’s structure and loading platforms are tailored for carrying, not for everyday road towing tasks. Each figure reflects a distinct mission profile and engineering choices.

The highest-rated conventional tractor unit stands apart because it is optimized for extreme haulage. Its design is not simply a scaled-up pickup. The chassis uses reinforced members and cross-bracing. Axle spacing and tire selection reduce road loading and distribute weight across more points. High-capacity fifth wheels, kingpins, or drawbar arrangements transfer massive forces safely. Powertrains pair high-displacement diesel engines with heavy-duty transmissions. The gearing emphasizes torque multiplication instead of speed. Cooling circuits use larger radiators, multiple fans, and sometimes heat exchangers for transmission and engine oil. Braking systems add retarder units and large-disc brakes with multi-circuit redundancy. These trucks can mercilessly strain components unless everything is engineered to match.

Torque, not horsepower, usually dictates towing capability. Diesel engines produce high torque at low RPM, which is essential for starting heavy loads and climbing grades. Torque determines the initial force to overcome inertia. Transmissions then convert torque into tractive force through gear reduction. Multi-speed automated manuals, range-split units, and crawler gears appear in combinations that give the driver or control system fine-grained command over power delivery. For the heaviest tows, low-speed control matters more than outright top speed. Creep ratios allow controlled movement under full load.

Axles and traction are equally crucial. Torque must be transmitted to the pavement without wheel slip. That requires adequate axle count, carefully tuned differentials, and sometimes inter-axle locking. More driven wheels improve traction and increase the truck’s ability to start a heavy load. Yet more axles mean more frictional losses and higher maintenance complexity. Designers balance traction needs with weight distribution rules and tire load ratings. For the largest towing tasks, additional non-driven axles support weight and preserve road surfaces.

The coupling system and trailer type change how capacity is calculated. Towing a load on a fifth-wheel platform transfers a portion of the trailer weight onto the tractor’s rear axles. Drawbar or pintle couplings behave differently and often reduce the on-axle load allowed. Lowboy and hydraulic modular trailers spread weight across many axles, lowering per-axle loads and staying within legal road limits. Self-propelled modular transporters (SPMTs) exist for loads beyond road limits, but they are not conventional trucks. When a tractor is said to tow 912 tons, that number assumes a compatible trailer system that spreads that mass while maintaining stability.

Safety systems scale up with towing capacity. Large tows need redundant braking circuits, supplemental retarders, and fail-safe systems. Electronic stability controls and load-sensing valves modulate braking across axles. Steering geometry and articulation points are designed to avoid jackknifing and to maintain maneuverability. Winches and hydraulic booms often provide initial pull and fine positioning. Outriggers and ballast modify the center of gravity during extreme recovery operations. Crew training becomes part of the safety system; an untrained operator can create catastrophic risk even with the most capable machine.

Regulatory and infrastructure constraints limit practical towing more than raw mechanical capability. Road weight limits, bridge ratings, and permitting rules determine how heavy a tow may legally travel on public roads. Routes must be planned to avoid low-clearance structures and weak bridges. Municipal permits often require police escorts and temporary road closures. Transporting extremely heavy loads commonly involves engineering surveys and traffic management plans. Even if a truck can pull 912 tons, it cannot ignore the bridges it crosses or the sharp corner it must negotiate.

Different tasks call for different machines. Wreckers use concentrated winch and boom geometry to extract disabled vehicles. Tank transporters prioritize platform stability and loading ramps. Extreme heavy-haul tractors emphasize sheer tractive force and the ability to mate to modular trailers. The metrics used differ. A wrecker’s rated pull may reflect winch capacity under ideal mechanical advantage. A military transporter lists payload capacity for carrying armored vehicles. A heavy haul tractor’s rating often considers the coupled trailer’s dynamics and assumes highway conditions.

Maintaining these machines requires specialized knowledge. High-torque driveline components undergo intense stresses. Regular inspection of universal joints, driveshafts, and gearbox bearings prevents failures. Tires supporting hundreds of tons across multiple axles must be monitored for heat and pressure. Brake material wear scales with load and distance. Cooling system maintenance prevents overheating during slow, heavy pulls. Fleet managers for extreme-haul operations often keep spare components and trained technicians on call.

Operational strategies matter when attempting the largest tows. Starting a massive load requires staging. Operators may use a controlled winch setup anchored to a stable point to take initial slack out. Progressive pulling leverages lower gears and a slow, steady throttle to avoid torque spikes. Hill starts may need assistance from additional tractors or specialized push units. In some operations, multiple tractors work in concert using remote-controlled linkages or synchronized throttle control. Coordination between drivers and ground crews ensures safe coupling and load positioning.

Fuel consumption of extreme-haul tractors is significant. High torque and heavy loads mean engines run in low gears for extended periods, consuming much more fuel than typical highway operation. Fuel planning becomes part of route preparation. Often, service logistics include tanker trucks and support vehicles that follow the main convoy to refuel and attend to mechanical needs. For prolonged moves, crews schedule maintenance stops to inspect running gear and perform fluid checks.

Economic trade-offs influence choosing the right truck. The most powerful tractors incur higher acquisition and operating costs. They also have lower flexibility; you cannot easily use a nine hundred-ton-rated tractor for light local deliveries. Many operators prefer a fleet mix: general heavy-duty tractors for daily hauling and a few specialized extreme-haul units reserved for exceptional projects. Renting an extreme-haul tractor or hiring a specialized transport provider can be more cost-effective for one-off moves.

Real-world examples underscore the differences between raw ratings and practical operation. An eight-axle industrial tractor might list a high theoretical towing number. Yet in practice, soil conditions at the site, road width, and available trailer equipment determine what can move. A military transporter with a two hundred-ton rating excels at carrying armored loads within a logistical chain. A heavy-duty wrecker rated for one hundred tons demonstrates superior recovery capability in vehicle incident work. None of these figures are directly interchangeable; they express capability within a particular design envelope.

Maintenance of route integrity plays a hidden role. Asphalt and concrete react differently under extended heavy loads. A concentrated load can rut soft shoulders, damage pavement, or crack bridge decks. Transport planners often use temporary matting, steel plates, or engineered bypasses. When moving extremely heavy loads through populated areas, local authorities may require strengthening measures or temporary structural reinforcements.

Human factors remain critical. Operators managing the largest tows often have advanced licenses and certifications. They receive training in coupling heavy trailers, weight distribution, and emergency procedures. Communication protocols between tug drivers, escort vehicles, and traffic control must be precise. Even the best machine is only as safe as its operator’s decisions.

Understanding towing capacity also means distinguishing between towing and carrying. Payload refers to weight placed on or inside the truck itself. Towing capacity refers to the weight a truck can safely pull on a trailer. A vehicle that carries heavy loads on its bed may not pull similarly heavy loads on a drawn trailer. Coupling forces and load dynamics diverge, and engineering focuses on different structural points.

For owners and operators wondering about personal or commercial towing limits, practical tools exist. Calculators and manufacturer guidance translate gross combined vehicle weight ratings into realistic limits. For smaller-scale towing, this internal guidance is helpful. For the extremes discussed here, the numbers exist only because of a chain of compatible equipment, trained personnel, and legal clearances. If you want to understand the capacity of your regular truck, consult guidance like the resource on the amount a truck can tow: how much can my truck tow.

In summary, the highest towing capacities are dominated by specialized heavy tractors engineered for extreme haulage. A top-rated unit in the available datasets shows a theoretical towing rating in the vicinity of nine hundred and twelve tons. That number is a function of reinforced structures, high-torque powertrains, multi-axle traction systems, heavy-duty cooling and braking, and compatible trailer systems. Other heavy rigs show strong capability at one hundred to two hundred tons, but they serve different roles.

Evaluating which truck has the highest towing capacity is not merely a matter of reading a spec sheet. It demands a holistic view of design, purpose, and operating context. The most powerful tractor unit is unmatched in raw towing numbers, but its utility depends on matching trailers, route approvals, and logistical support. For most users, heavy-duty commercial trucks offer ample towing for everyday and industrial needs. When operations require the extraordinary, extreme-haul tractors deliver an unmatched combination of force and control.

For a technical deep dive into diesel pulling trucks, gear choices, and the standards that underpin towing performance, refer to this detailed guide: https://www.truckpaper.com/diesel-trucks-for-sale/technical-guide-to-diesel-pulling-trucks

Power Without Compromise: Engineering Secrets Behind Record-Towing Trucks

When asking which truck can move extraordinary mass, a shift from peak horsepower to deliberate engineering follows. The Volvo FH16.8×8 tractor unit emerges as the standout, with a towing capacity measured in hundreds of tons. The 912-ton rating highlights a design tuned for extreme load bearing, traction, and safety under conditions that overwhelm ordinary trucks. Understanding why requires looking at engine torque, robust chassis and suspension, the drive-line, and advanced control systems that monitor and protect both machine and payload. The eight-axle configuration distributes weight to maintain stability and limit tire wear, while modern suspensions adapt to road conditions and payload distribution. The powertrain must deliver sustained trActive effort, not just a high peak; torque at low RPM helps overcome inertia and gradients. The drive-line must handle this torque without overheating or slipping, aided by electronic braking, ABS, and stability controls. Material science supports higher capacities with stronger, lighter components, improving strength-to-weight and fuel efficiency. Real-world operation also depends on planning, route choice, and risk assessment, aided by GPS and fleet-management systems. These networks enable recovery fleets to minimize downtime and ensure legal weight distributions. The FH16.8×8 represents a civilian, certified high-capacity solution built for standard freight environments, whereas some military platforms or tank transports push even higher limits in different contexts. The chapter closes with a reminder that the capacity ceiling is shaped by purpose, safety frameworks, and the coordination of engineering disciplines across powertrains, frames, suspensions, and controls.

Final thoughts

The Volvo FH16.8×8 stands unrivaled in the realm of towing capacity, making it the ideal choice for trucking companies, property managers, and any entity that requires heavy-duty transport capabilities. Its impressive towing capacity and engineering innovations set a new benchmark, outpacing competitors like the British Iveco X-Way and the Peterbilt wrecker. Understanding these capabilities helps consumers make informed decisions, whether for business or personal use. Ultimately, the advancements in technology that allow the FH16.8×8 to achieve such feats reflect a larger trend in the industry toward performance and safety, paving the way for the future of heavy-duty trucking.