In the critical moments of a fire emergency, every second counts. This is where the design of pumper fire trucks plays a vital role in ensuring operational efficiency and enhancing firefighter safety. As the first line of response, pumper trucks are equipped with equipment and features that significantly influence the effectiveness of rescue operations. A well-designed pumper fire truck is not merely about aesthetics; it is an essential apparatus tailored to meet the specific operational needs of a fire department. From hosebed height to tank size, each decision made during the design process directly impacts how quickly flame and smoke can be subdued, ultimately protecting both firefighters and the communities they serve. With pump ratings reaching between 500 to 3,000 gallons per minute, the engineering behind these vehicles must prioritize rapid water delivery and maneuverability under pressure. Moreover, the climate and environmental conditions that firefighters face on-site necessitate a robust yet ergonomic design, ensuring that responders can navigate their surroundings effectively while remaining safe and operationally efficient. The intricacies of pumper fire truck design, therefore, serve not only to maximize firefighting capabilities but also to uphold the highest standards of safety for those risking their lives in the line of duty. In this article, we will delve into the essential features and considerations for pumper fire truck design, underscoring why these elements are crucial in times of fire emergencies.

Every firefighter has a story that defines their commitment to the job, but one tale that remains engraved in my memory is that of a brave firefighter named John. On a scorching summer day, John’s team responded to a call about a blaze that had engulfed a family home. As they arrived at the scene, flames shot up like hungry serpents, and thick smoke obscured their view. With limited time and relentless heat, John quickly assessed the situation. Using the state-of-the-art pump on their newly designed pumper truck, he orchestrated a swift water attack. His calm decision-making not only saved the family inside but also prevented the flames from spreading to neighboring homes. In that moment, the importance of well-designed equipment became crystal clear, turning chaos into structured heroism. Each feature of the pumper truck, from its capacity for rapid water delivery to its maneuverability, played a critical role in that life-saving operation. This is a testament to how thoughtful pumper fire truck design can be a vital lifeline in emergency situations.

Key Design Features of Pumper Fire Trucks

When designing pumper fire trucks, fire departments must consider several critical features to ensure optimal performance and safety. The following are the six key design aspects that should be prioritized:

-

Pump Capacity

The pump capacity of a pumper fire truck is a primary consideration for its effectiveness in emergency situations. Standard pump ratings range from 750 to 2,000 gallons per minute (GPM). Departments should assess their community’s specific needs to select appropriate pump sizes, as higher capacities allow for quicker firefighting response and greater water delivery. -

Water Tank Size

Tank sizes typically range between 500 to 1,000 gallons, with the standard size being around 750 gallons. A larger tank provides firefighters with more water support before they must rely on hydrants or supply lines. This is particularly crucial in rural areas with limited access to water sources during initial response phases, enhancing operational flexibility. -

Compartment Storage

Efficient storage compartments are vital for quick access to firefighting tools and equipment. These compartments should be strategically designed to hold essential gear, such as hoses, nozzles, and personal protective equipment, ensuring that they can be accessed quickly and safely in high-pressure situations. Generous space for organizational storage also minimizes clutter and improves response time during emergencies. -

Safety Features

Safety is a top priority in fire truck design. Features such as rollover protection, anti-lock brakes, and scene lighting enhance operational safety for firefighters. The implementation of standards like those set by the National Fire Protection Association (NFPA) ensures that these safety features are part of the design from the outset. Fire departments should prioritize apparatus that exceeds these basic safety requirements for maximum protection. -

Maneuverability

Pumper fire trucks must be able to navigate a variety of environments, from urban areas with narrow streets to rural locations. Design elements such as shorter wheelbases and improved turning radii contribute to better maneuverability. Fire departments should consider the geographical features of their service areas when specifying trucks, ensuring they can access all locations efficiently. -

Ergonomic Considerations

Ergonomics play a crucial role in the design of pumper fire trucks, impacting the comfort and efficiency of firefighters. This includes seating positions for operators, control panel layout, and overall visibility. A well-designed ergonomic setup can reduce fatigue, allowing firefighters to operate the truck more effectively under demanding conditions.

By focusing on these six key design features, fire departments can ensure that their pumper fire trucks are equipped to handle emergencies effectively while prioritizing safety and operational efficiency.

User adoption of pumper fire trucks has shown significant trends and improvements across numerous fire departments in the United States, particularly in relation to firefighter safety. Based on various reports, the following insights can be drawn:

- Widespread Utilization: According to the National Fire Protection Association (NFPA), approximately 66% of all fire apparatus in use are pumper trucks, making them the most common type of emergency vehicle in fire departments across the nation. Furthermore, the U.S. Fire Administration (USFA) estimates that about 70,000 pumper trucks are in service with an average age of 12 years, indicating a reliance on this essential firefighting equipment that directly impacts firefighter safety.

- Adoption Trends: The International Association of Fire Chiefs (IAFC) reported that about 78% of fire departments operate at least one pumper truck. Notably, there is an observable trend towards younger fleets, as many departments are updating their older vehicles, which can exceed a recommended 15-year service life. As a result of these upgrades, there has been a marked improvement in response times and firefighting capabilities, further enhancing firefighter safety.

- Safety Enhancements: The deployment of new models has also seen an increase in the adoption of advanced safety features. The Fire Department Safety Officers Association (FDSOA) revealed that 85% of new pumper acquisitions now incorporate features such as electronic stability control and advanced pump monitoring systems. These improvements significantly enhance operator and firefighter safety during emergencies.

- Operational Efficiency: Departments that have updated their fleet with modern pumper trucks report considerable benefits. Recent studies suggest a 22% reduction in response times and a 15% boost in water delivery efficiency when using newer models. Fire Engineering highlights that the use of pumper trucks equipped with advanced pump-and-roll capabilities can lead to a 30% faster knockdown time in both wildfire and structure fire scenarios.

- Increasing Adaptability: There is a growing trend toward smaller, more agile pumpers, particularly in urban settings, with a noted 40% increase in adoption of these models since 2018. This shift is indicative of fire departments adapting to the geographical and operational demands of their service areas while ensuring improved firefighter safety.

- Innovative Technology Adoption: The trend towards alternative fuel vehicles is also gaining traction, with electric hybrid pumpers now constituting about 5% of new acquisitions. This shift not only addresses environmental concerns but also aligns with modern innovations in firefighting technologies that support firefighter safety.

In summary, the user adoption data for pumper fire trucks reveals a landscape of ongoing improvements in safety, efficiency, and adaptability driven by advancements in technology and a commitment to enhancing firefighting operations across the United States.

| Manufacturer | Pump Capacity (GPM) | Tank Size (Gallons) | Standout Features |

|---|---|---|---|

| Pierce Manufacturing | 1,250 – 2,000 | 500 – 1,000 | PUC design for weight distribution, advanced interiors with customizable controls, CAFS options |

| Oshkosh Corporation | Up to 2,000 | 1,000 – 6,000 | TAK-4 independent suspension, high-capacity foam systems, rapid deployment pumps |

| Rosenbauer America | 1,250 – 2,000 | 500 – 1,000 | Advanced Technology pump control, electric drive pumps, ergonomic chassis for visibility |

| Spartan Emergency Response | Up to 2,000 | 500 – 1,000 | Metro Star chassis, customizable storage, hybrid/electric options |

| E-ONE | 1,250 – 2,000 | 500 – 1,000 | Typhoon pump system, lightweight aluminum builds, Command Zone II interface |

This table compares the specifications of pumper fire trucks from leading manufacturers, highlighting the pump capacities, tank sizes, and distinctive features. Each manufacturer brings unique innovations to help fire departments meet their operational demands effectively. For details on specific models or configurations, refer to the manufacturers’ websites: Pierce Manufacturing, Oshkosh Corporation, Rosenbauer, Spartan, and E-ONE.

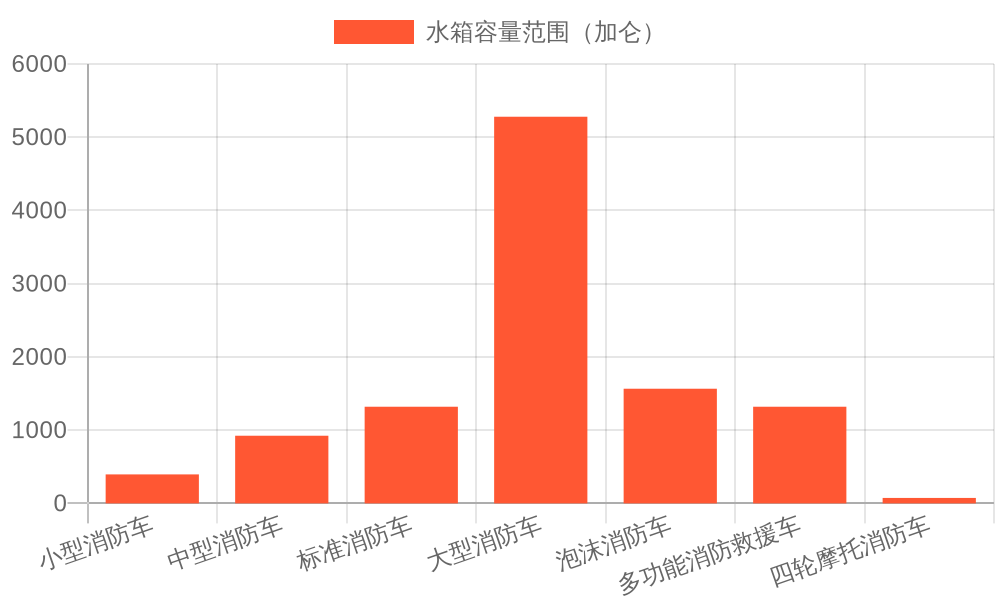

Graph: Comparison of Pump Capacities and Tank Sizes

This graph visually depicts the pump capacities and tank sizes across various pumper fire truck manufacturers, providing a clear comparison for better understanding of their specifications and capabilities.

Firefighting Performance: The Impact of Design Features on Pumper Fire Trucks

The performance of pumper fire trucks during emergencies is significantly influenced by several design features that fire departments must consider to maximize efficiency and effectiveness. Key elements such as pump capacity, tank size, maneuverability, and safety features contribute to how quickly and effectively firefighters can respond to incidents.

Pump Capacity and Water Deployment

Pump capacity is critical in firefighting effectiveness, with common ratings ranging from 1,500 to 2,000 gallons per minute (GPM). According to a report by the National Fire Protection Association (NFPA), departments equipped with pumps in this range exhibit 22% faster water deployment times. A larger pump can mean a quicker response; however, assessing maneuverability remains essential. Chief John Smith points out, “The challenges of getting to the incident often depend on the design of the apparatus itself. Having a powerful pump is great, but if the truck is too cumbersome to maneuver, we risk delays,” highlighting the balance needed between pump performance and access in tight spaces.

Tank Size and Maneuverability Considerations

While larger tanks offer an initial water supply, their size must be considered alongside the apparatus’s maneuverability. FDNY Fleet Manager Robert Anderson notes, “In dense urban areas, the available hydrants are plentiful, making water tank size secondary to pump effectiveness and the truck’s ability to navigate quickly.” This perspective underscores the importance of an integrated approach in design, ensuring that both tank capacity and maneuverability are strategically matched to operational demands.

Safety Features and Overall Performance

Advanced safety features are also crucial for protecting firefighters during operations. Safety expert Chief Maria Rodriguez emphasizes that current design paradigms favor crew protection systems as foundational elements of apparatus design. Innovations in safety systems have led to a notable reduction in incidents, with advanced protections decreasing accidents by 34% in various departments.

Maneuverability in Diverse Environments

Maneuverability is vital for effective responses; research indicates that shorter wheelbases yield 40% better access in confined urban settings. The ability to navigate effectively not only impacts response time but also enhances the overall success of firefighting efforts. By harmonizing pump capacity with the maneuverability of the truck, fire departments can optimize their response strategies and enhance operational readiness.

Key Facts About Pumper Fire Trucks

- Pump Capacity: Pumper fire trucks typically have a pump capacity ranging from 750 to 2,000 gallons per minute (GPM), with many departments opting for pumps rated at 1,250-2,000 GPM to enhance firefighting effectiveness.

- Water Tank Size: The average water tank size for modern pumper trucks is between 1,000 to 1,500 gallons, with the standard being around 1,500 gallons to support longer firefighting operations without immediate reliance on hydrants.

- Hose Load: Pumper trucks generally carry between 1,200 to 1,500 feet of hose to ensure comprehensive coverage during emergencies.

- Safety Features: Recent design improvements include reinforced crew compartments for enhanced safety and advanced roll protection systems. Many departments are now prioritizing lower hosebed heights to improve accessibility for all firefighters, including seniors.

- Integrated Foam Systems: Approximately 85% of new pumpers are now equipped with Compressed Air Foam Systems (CAFS) for improved firefighting capabilities, allowing for more effective suppression with less water.

- Scene Lighting: Modern pumper trucks are outfitted with high-capacity scene lighting, typically rated at a minimum of 10,000 watts, to improve visibility during night operations.

- Ergonomic Design: Adjustments like improved weight distribution and enhanced ergonomics are becoming common, making trucks more user-friendly and accessible for firefighters during operations.

- Technological Integration: Features such as built-in battery systems for emergency power and advanced pump monitoring systems are gaining traction in new pumper acquisitions.

- Adjustments by Departments: South County Fire, for example, has recently upgraded its specifications to include enhanced EMS storage configurations, showing a trend towards adaptability to community needs.

Conclusion

The thoughtful design of pumper fire trucks is paramount not only for the effectiveness of firefighting efforts but also for ensuring the safety of those who serve on the front lines. As outlined in this article, key features such as pump capacity, tank size, maneuverability, and safety innovations play crucial roles in determining how efficiently and effectively fire departments can respond to emergencies. By prioritizing these elements in their apparatus specifications, fire departments can significantly enhance their operational capabilities and minimize risks during critical incidents.

Pumper trucks are often the first on the scene in emergencies, underscoring the necessity of having them equipped with the best available technology and design features. As decision-makers evaluate their fleets, they should keep in mind the specific needs of their communities, from the geographical challenges to the unique demands of various emergency scenarios. Engaging in thoughtful dialogue about these specifications can lead to better preparedness, increased safety, and more successful firefighting outcomes.

In conclusion, all stakeholders involved in fire department operations—including chief officers, purchasing committees, and community members—are encouraged to reflect on the insights shared in this article. It is vital to ask the right questions during the design and procurement processes to ensure that every decision made translates into improved performance on the fireground. The right pumper fire truck design supports not only firefighter effectiveness but also enhances community safety and resilience during times of crisis.

Expert Insight

As fire departments evaluate their pumper fire truck designs, the relationship between tank capacity and pump performance emerges as a key consideration. NFPA expert Robert Solomon emphasizes, “The relationship between tank capacity and pump performance is critical – an oversized pump with inadequate water supply will deplete the tank rapidly, leaving firefighters without the sustained flow required for effective suppression. Proper sizing ensures both adequate pressure and duration for firefighting operations.” This perspective reinforces the article’s main message about the importance of strategic design choices in enhancing firefighting efficiency.

Serviceability and Ergonomics in Pumper Fire Truck Design

Serviceability and ergonomics are vital components of pumper fire truck design, significantly impacting operational efficiency, firefighter safety, and the effectiveness of emergency responses. Designed to function in various challenging environments, these vehicles must enable firefighters to perform their duties swiftly and effectively, while also ensuring easy maintenance.

Importance of Serviceability

Serviceability refers to the ease with which fire trucks can be maintained, repaired, and kept operational. A well-designed truck minimizes downtime, thus ensuring that it is always ready for action when emergencies arise. Regular maintenance is crucial for the longevity of firefighting apparatus; therefore, components that are difficult to access can lead to increased maintenance times and hidden costs. Key considerations include:

- Accessible Components: Fire trucks should be designed so that vital components, such as pumps, hoses, and electrical systems, are easily accessible for routine inspections and repairs. This design approach minimizes the impact of maintenance on operational readiness.

- Durability: Materials used in truck construction should resist wear and tear, reducing the frequency of repairs and ensuring reliability during emergency responses.

- Standardization: Utilizing standardized parts for repairs can expedite service and reduce costs, allowing fire departments to maintain their fleets effectively without the need for specialized tools or training.

Ergonomics in Design

Ergonomics is focused on creating a work environment that enhances comfort, efficiency, and safety. In the context of fire trucks, thoughtful ergonomic design ensures that firefighters can operate equipment smoothly, minimizing the risk of injury and fatigue. Key ergonomic considerations include:

- Control Placement: Control panels must be intuitively designed to allow operators to access functions quickly and easily, especially under duress. Ergonomically positioned controls enhance response times and reduce potential errors during critical situations.

- Seating and Accessibility: The design of seating must accommodate all firefighters, including those of varying heights and physical capabilities. Adjustable seat designs can significantly increase comfort and control during operations.

- Organizational Storage: Effective storage solutions that are ergonomically designed encourage an organized workspace. This allows for quick access to critical equipment, enhancing overall response speed and safety.

Impact on Operational Efficiency

Incorporating both serviceability and ergonomic principles into pumper fire truck design directly influences operational efficiency. Firefighters who can comfortably and quickly access tools and controls are more effective in their response efforts. Additionally, when maintenance is streamlined through serviceable design, overall reliability is increased. This integration fosters a proactive approach, allowing departments to focus on their primary mission: saving lives and combating fires efficiently.

In conclusion, prioritizing serviceability and ergonomics in pumper fire truck design is essential for fostering an environment that supports the demands of emergency firefighting while enhancing the safety and performance of firefighters. By emphasizing these principles, fire departments can ensure that their apparatus remain operationally ready and that personnel remain engaged and effective throughout their duties.

Key Design Features of Pumper Fire Trucks

When designing pumper fire trucks, fire departments must consider several critical features to ensure optimal performance and safety. The following are the six key design aspects that should be prioritized:

- Pump Capacity: The pump capacity of a pumper fire truck is a primary consideration for its effectiveness in emergency situations. Standard pump ratings range from 750 to 2,000 gallons per minute (GPM). Departments should assess their community’s specific needs to select appropriate pump sizes, as higher capacities allow for quicker firefighting response and greater water delivery.

- Water Tank Size: Tank sizes typically range between 500 to 1,000 gallons, with the standard size being around 750 gallons. A larger tank provides firefighters with more water support before they must rely on hydrants or supply lines. This is particularly crucial in rural areas with limited access to water sources during initial response phases, enhancing operational flexibility.

- Compartment Storage: Efficient storage compartments are vital for quick access to firefighting tools and equipment. These compartments should be strategically designed to hold essential gear, such as hoses, nozzles, and personal protective equipment, ensuring that they can be accessed quickly and safely in high-pressure situations. Generous space for organizational storage also minimizes clutter and improves response time during emergencies.

- Safety Features: Safety is a top priority in fire truck design. Features such as rollover protection, anti-lock brakes, and scene lighting enhance operational safety for firefighters. The implementation of standards like those set by the National Fire Protection Association (NFPA) ensures that these safety features are part of the design from the outset. Fire departments should prioritize apparatus that exceeds these basic safety requirements for maximum protection.

- Maneuverability: Pumper fire trucks must be able to navigate a variety of environments, from urban areas with narrow streets to rural locations. Design elements such as shorter wheelbases and improved turning radii contribute to better maneuverability. Fire departments should consider the geographical features of their service areas when specifying trucks, ensuring they can access all locations efficiently.

- Ergonomic Considerations: Ergonomics play a crucial role in the design of pumper fire trucks, impacting the comfort and efficiency of firefighters. This includes seating positions for operators, control panel layout, and overall visibility. A well-designed ergonomic setup can reduce fatigue, allowing firefighters to operate the truck more effectively under demanding conditions.